As soon as humans took to the water, they needed a means of holding their boats in position. The pull of the tide, the flow of a river, or the push of the wind all threatened to carry them toward danger. The very first anchors likely were developed by early fishermen looking to keep their boats above a promising location. These probably consisted of a simple weight, perhaps a large stone or a basket of rocks, attached to a line, and this template influenced the earliest known anchors.

In the Bronze Age, civilizations started to develop seagoing versions of their river and shallow-water boats to trade with neighbors and fish in deeper waters. These early ships needed anchors, too, and mariners developed larger versions to match the larger boats. The most common type was a pierced stone. Hundreds of these have been found by divers in ancient harbors dotted around the Mediterranean, Persian Gulf, and coast of India. In weight, they range from 14 pounds to half a ton.

The form varied by location. The ancient Egyptians, some of the earliest recorded seafarers, shaped theirs from an elongated block with a hole and channel cut near the top to take a cable, not unlike a ship’s sounding lead. Those from the Indian Ocean tended to be torus shaped—like a doughnut, circular with a hole through the center. Arab traders used these ring-stone anchors well into the early medieval period, until they encountered Portuguese ships with European anchors.

Some stone anchors show a surprising degree of sophistication. Honor Frost, a pioneer of underwater archaeology, identified several different types in use in the Mediterranean. These included ones she called “sand anchors,” with three or more additional round holes drilled through the stone. She concluded that these would have had wooden rods in them behaving like later anchors’ flukes, providing more grip on the seafloor.

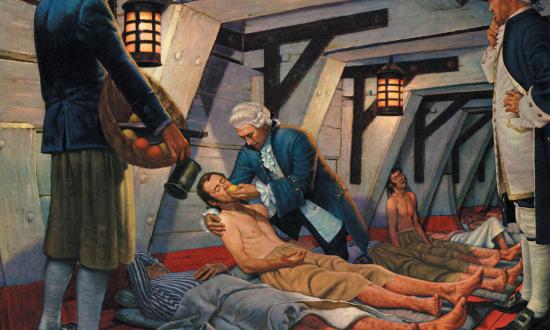

As commerce flourished, trading ships grew and were joined by still larger warships to protect them. Bigger vessels required ever-larger stone anchors, until they became too cumbersome to stow and handle on board. One solution to this dilemma was to replace stone with denser materials. There is evidence of Phoenician and Greek traders using hollowed-out tree trunks filled with lead. In the second millennium BC, Chinese sailors used lengths of iron chain. But, eventually, the size of ships required something more than simple reliance on weight alone.

From around 600 BC, the Greeks began to use iron anchors designed to catch in the seabed. Initially, there was a variety of designs, including ones with three or even four arms, akin to a large grappling hook. But from 450 BC, the same design begins to appear consistently on coins, ceramics decorated with ships, and in mosaics. This anchor had a single shaft branching to form two opposed hooks. Mounted at the top of the shaft at right angles was a bar called a stock, together with a ring on which to bend an anchor cable. The Greek word for a hook is ἄγκυρα (pronounced “ánkura”), from which we get “anchor.”

Iron anchors from this period have not survived in the same prolific numbers as stone versions, but there are some. One notable example appeared in the 1930s at Nemi, Italy, when two Roman ceremonial barges belonging to Emperor Caligula were excavated from the bed of an ancient lake. Thanks to the oxygen-free environment of the mud that entombed them, the anchors had been preserved. With the exception that the arms lacked triangular flukes, these anchors had an instantly recognizable classic shape.

In his 1622 Seaman’s Dictionary, Sir Henry Mainwaring gave one of the first technical descriptions of what is commonly known as the “Admiralty” or “fisherman’s anchor.” As well as naming the parts (stock, fluke, etc.), he also listed a technical specification. The “shank is thrice as long as one of the flukes, and half the beam,” for example. Although he wrote about the anchors of his day, his description applies equally well to the Roman examples from Nemi and those of the USS Constitution in Boston Harbor.

It is difficult to think of many technological innovations that have remained essentially unchanged for more than 2,000 years. But the explanation lies in the near perfection of the design. The stock prevents the anchor from lying flat on the seabed, so that however it strikes, one of the two arms should always catch. The angle of the arm is just right to drive the fluke deeper when subjected to a lateral pull, such as by a ship drifting on the surface. But thanks to the leverage of its long shank, the anchor will yield to the vertical pull of a crew hauling it up.

As the centuries passed, ships continued to grow in size. Hulls with more windage exerted greater pull and so needed larger anchors. By the end of the 18th century, a first-rate ship-of-the-line such as HMS Victory had four main anchors, each one weighing 8,400 pounds, with a stock that was more than 23 feet wide. Such enormous anchors were both difficult to handle and awkward to stow, having to be lashed to the outside of the hull.

As the 19th century dawned, there was little sign that the relentless increase in the size of ships would slacken, leading to ever more awkward anchors. One solution was to redesign the stock so it could pivot onto the same plane as the flukes, permitting the anchor to be stowed flat. This solution lasted until the first all-iron ships signaled a revolution that would produce vessels of previously unimaginable tonnage. Now the problem caused by exceptionally large fisherman-style anchors was not just one of stowage. When deployed on the seabed, whichever arm has not caught sticks up. This means that, if the ship turns around her anchor with a change in tide or wind, her cable may well foul on this hook and pull the anchor free. The larger the anchor, the more prominent the arm, and so the greater the risk.

The solution was a fundamental redesign. The French firm of C. Martin and Sons came up with one of the first examples. The Martin’s anchor had a short, fixed stock and arms that rested in the same plane but pivoted through an angle of 30 degrees. It was much easier to stow on board since it could lie flat on the deck. When dropped, a combination of the weight of the arms and the drag of the ship caused the flukes to catch and pivot downward, digging into the seabed. Because both flukes were buried, there was little risk of fouling the cable. From the Martin anchor, it was a short step to the stockless anchors that predominate today.

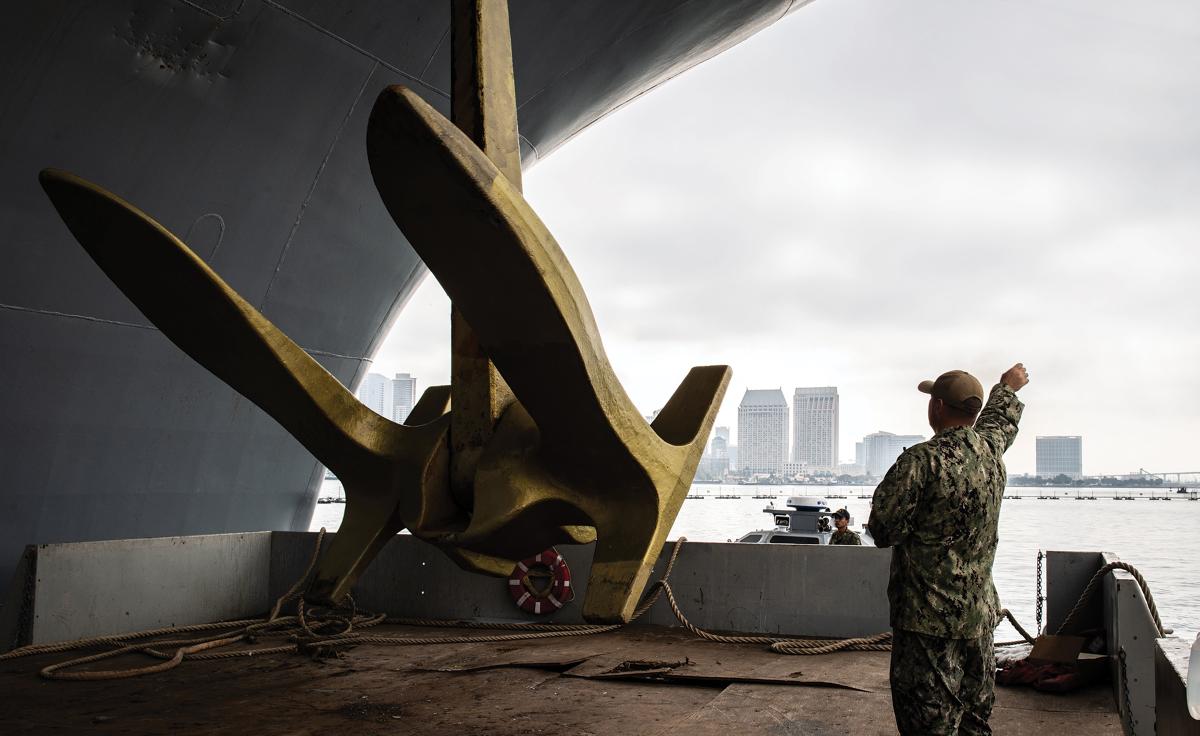

They come in numerous designs, but they all share the same fundamental advantages. The arms pivot in much the same way as a Martin anchor, ensuring that they bury themselves when dragged along the seabed. The lack of a stock permits the shank to be pulled into the hawsehole of the ship, leaving the flukes flat against the side, which solves the problem of stowage. Finally, no matter how large the ship, they can be scaled up, even beyond the truly monstrous 30-ton examples on the largest U.S. aircraft carriers today.

The classic Admiralty anchor may have disappeared from everyday use, but it still lives on as the nearly universal symbol representing seafaring. On the buttons and badges of military and civilian naval uniforms alike, in every corner of the world, you will find it—a fouled version signifies a U.S. Navy chief petty officer. One is gripped in the eagle’s claws on the U.S. Navy’s seal, while two examples are crossed on every officer’s cap badge. It appears on the mugs and tea towels to be found in any gift shop within sight of the sea. It may obsolescent now, but, is very much still with us.