With the rapid spread of COVID-19 in 2020, the U.S. Department of Defense (DoD) instituted international and domestic travel restrictions to slow the spread of this serious disease. This affected not only DoD acquisition programs, but also U.S. allies’ and foreign partner countries’ weapon system acquisition programs. Some foreign governments have a strategic partnership with the United States that allows them to procure weapon systems through foreign military sales (FMS) programs. The FMS programs are a backbone of security cooperation between the United States and its allies. The scale of FMS is increasing, and “in fiscal 2019, the Navy implemented 1,390 FMS cases worth $12.74 billion.”1

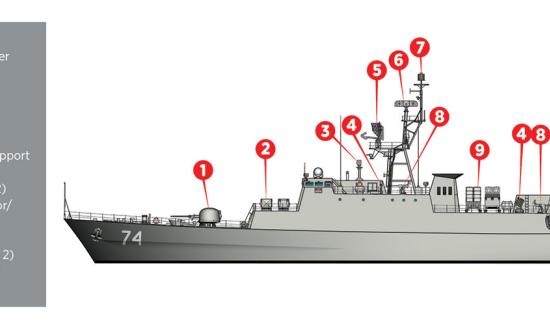

To respond to the growing threats from North Korea, the Republic of Korea (ROK) decided to procure three more Aegis combat systems through the FMS KDX-III Batch-II Aegis Program. In 2015, the U.S. State Department approved the sale of Baseline 9 Aegis combat systems and associated equipment, Mk 41 vertical launch systems, parts, and logistical support valued at an estimated $1.91 billion. This will add top-notch ballistic-missile defense (BMD) capabilities to the ROK Navy. Baseline 9 enables the ROK Navy to contribute to the stability of the entire East Asia region.

With the KDX-III Batch-II Aegis Program, the ROK is not simply buying an already assembled combat system. The program needs to work through the weapon system development and acquisition process through a collaboration between the United States and the ROK. There are numerous U.S. defense contractors and various U.S. government agencies involved in the program to meet the ROK Navy’s requirements. Since the beginning of the program, both governments have had several program management reviews and working group meetings each year to ensure seamless program and supply-chain management. Prior to the COVID-19 pandemic, all meetings were held in person, either in Korea or in the United States. However, the pandemic has made a significant impact on the structure of the meetings and program management. It has slowed the decision-making and pace of communication between ROK and U.S. program offices.

Leveraging Communication Technologies

Most countries have established two weeks of self-quarantine for international travelers. Some of them ask visitors to stay in a government-designated facility for two weeks at the visitor’s own expense. Also, various governments encourage teleworking to ensure the safety of both government and industry employees. However, not all workplaces are ideal for teleworking. Some work areas, production lines, transportation systems, etc., require in-person activity and engagement. In fact, in-person engagement is key to streamlining and clarifying FMS customer requirements at the early phase of an international weapon-system acquisition program.

COVID-19 restrictions have caused process, transportation, and delivery delays. The program offices have been using existing IT to overcome the obstacles, such as web conferences with WebEx and Microsoft Teams, although the 13-hour time difference between the two countries gives a limited window for a web video conferencing. However, we have overcome this to an extent by stretching the length and frequency of meetings.

In terms of software development, we have been able to use a virtual server, which enables certified terminals to connect to the server to develop weapon system software and complete a certification process. In addition, we can use the “internet of things” to increase the visibility in supply chains, especially to manage inbound and outbound shipments. By simply scanning a quick response (QR) code or barcode, we can easily locate a shipment. This also allows people to access all shipping documents in a database server. It improves the efficiency in customs clearance and international shipment processes, compared with the typical process using paper-based documentation per shipment. These information technologies allow government and industry personnel to minimize exposure and reduce health risks while program offices manage the KDX-III Batch-II program effectively and efficiently without delaying it.

Greater Agility and Responsiveness

The restricted-travel policies of both countries have prevented program managers and subject matter experts from ROK’s Defense Acquisition Program Administration, the U.S. Navy’s systems commands, and each country’s defense industry from holding face-to-face meetings. Yet, we have a saying: “If you don’t have a dime, use two nickels.” Korea and the United States have sent representatives from their respective acquisition workforce to manage the KDX-III Batch-II Aegis Program, and they can be given more responsibilities and authorities for decision-making on technical matters. Each representative has at least ten years of program management experience. This is a good alternative to mitigating the pandemic-induced slow decision-making on the program’s management and increase responsiveness in the long run.

As USNI News noted, “[U.S.] defense contractors are experiencing the highest number of COVID-19-related work delays and closures.”2 The COVID-19 pandemic is placing added stress on some global suppliers of U.S. defense contractors that might cause delays in the manufacturing process for KDX-III Batch-II Aegis Program components. While technology transfer and the scope of work would need to be determined, opening a production line or subsidiary companies in Korea, or in any FMS partner country, can help alleviate this problem.

At the very least, this approach could be applied to the KDX-III Batch-II Aegis Program. The ROK defense industry is capable and has been involved in the Aegis program since early 2000 with the KDX-III Batch-I program. In the western Pacific, FMS partners Australia, Korea, and Japan are operating Aegis combat systems. Australia has three Hobart-class destroyers; Korea has three King Sejong the Great–class destroyers, and three more Aegis destroyers are under construction; and Japan has four Kongo-class, two Atago-class, and two Maya-class destroyers. If the United States established a production line in Korea to support ship construction and logistics support for the life cycle of the Aegis combat system, it would benefit all three FMS partners by reducing transportation costs, increasing resilience and agility, and establishing redundancy in the supply chains.

The COVID Opportunity

The COVID-19 pandemic has revealed vulnerabilities in FMS program management and has inflicted work delays and business closures on the defense industry. COVID-19’s economic impact on international programs and defense industries will not subside in the near future. The United States and FMS partners need to adapt the international programs efficiently and effectively to this reality. In the short term, they need to maximize the use of IT and organizational structure. In the long term, they need to collaborate with FMS partner countries in establishing host-nation production lines and supply chains. These steps can make the current FMS program management system more resilient, agile, and redundant.

1. John M. Doyle, “Leveraging Technology, Reliability to the World,” Seapower, April 2020, 26.

2. Ben Werner, “COVID-19 Mitigation Will Likely Cost Defense Industry $1 Billion,” USNI News, 10 June 2020.