In recent decades, the U.S. Navy’s approach to defending against antiship weapons could be summed up in three words: “Don’t get hit.” A combination of countermeasures, defensive missiles, close-in weapon systems, and even stealth is meant to keep enemy weapons from hitting U.S. ships. But the large numbers and widespread proliferation of Chinese and Russian antiship systems call that approach into question. Surface combatants will need to be able to absorb a strike and still fight. That means ship designers need to think anew about something that has been an afterthought for decades: armor.

For this generation, the lesson on armor was largely learned on the ground. Early in the post-9/11 conflicts, high casualty numbers resulted from the enemy’s widespread use of explosives, improvised explosive devices (IEDs) in particular. Protecting vehicles, troops, and structures became an immediate priority. Even before industry-developed products made their way to Iraq and Afghanistan, troops had modified soft-sided vehicles with crudely welded steel plates. By the mid-2000s, the Pentagon had spent billions to acquire up-armored personnel carriers, mine-resistant/ambush-protected vehicles, Hesco gabions (or, colloquially, Hesco barriers), and body armor for all. The lessons learned about armor among ground troops need to be applied to ships at sea.

‘Punched in the Mouth’

Innovations in armor must be part of the comprehensive survivability plan for future combatants. As boxer Mike Tyson once said, “Everyone has a plan till they get punched in the mouth.” “Don’t get hit” is a good theory—until the impact of the first strike. China’s YJ-18 antiship cruise missile delivers 660 pounds of high explosive at speeds approaching Mach 3 from as far away as 270 nautical miles.1 Surviving a hit from such a missile will not be easy, even with highly trained damage control teams. But advanced armor technologies can reduce the worst effects of a successful enemy strike. Combatants that compromise on armor will carry increased risk and find themselves desirable targets.

Many emerging technologies depend on lighter materials and greater speed. Such attributes can be valuable, but developers should not forget strength. Consider the 1982 sinking of the Argentine light cruiser General Belgrano during the Falklands War. Almost half a century earlier, the General Belgrano began her life as the U.S. Navy’s Brooklyn-class light cruiser USS Phoenix (CL-46). The ship’s belt armor was relatively thin, less than five inches in most places.2 (For reference, the belt armor on the Pennsylvania-class battleships was more than 12 inches thick.3)

On 2 May 1982, the World War II–era General Belgrano was struck by two World War II–era Mk VIII torpedoes packed with 805-pound Torpex warheads (though, curiously, the torpedoes were fired from a very modern nuclear-powered submarine, HMS Conqueror). Both unguided torpedoes struck areas without armor, causing structural failure in the hull and resulting in bow separation forward of turret number one. The General Belgrano was the fourth ship in her class (of nine total) to suffer bow separation from torpedo impacts.4 The fate of these Brooklyn-class cruisers is a lesson in the dangers of the compromise between strong and light and fast.

History offers many examples of armor’s value. The heavy scantlings of the USS Constitution possessed such superior strength and durability that they earned the ship the moniker “Old Ironsides” despite the absence of any metal armor, making her the match of any British frigate afloat in 1812. In 1859, France inaugurated the ironclad age with La Gloire to counter the advent of explosive shells from Paixhans naval guns.5 In the 1920s, the U.S. Navy’s “all-or-nothing” strategy sought to armor parts of ships most prone to attack—the conning tower, turrets, and magazines—balancing this with reduced protection elsewhere.6 In each example, the key link between armor and sea power is clear. An increased threat forced navies to pivot in the direction of enhanced physical defense. Today, the threat is again increasing, but so is armor technology.

Future manned surface combatants cannot count on avoiding or defeating every enemy shot fired. Designers will have to incorporate a variety of armor types from the beginning, to protect crews and improve ship survivability. But even for ships on the stocks today or already in service, there are options for modest improvements.

Opportunities on the Horizon

The Navy decided to build its new Constellation-class frigates, formerly known as the FFG(X), while “developing no new technologies or systems for the FFG(X)—the ship is to use systems and technologies that already exist or are already being developed for use in other programs.”7 Despite these constraints, innovations in the use of armor are necessary. There are opportunities to embrace emerging armor technology without drastic changes from the selected hull design, which is based on Fincantieri’s European multimission FREMM design.

For other surface combatant classes, selected restricted availability and other maintenance periods could be occasions to increase protection without making major structural changes. Innovations in reactive armor, ceramics, fabrics, and liquids—many driven by the need to respond to IEDs—could quickly improve ship survivability, at least in some circumstances.

Reactive armor. Often found on tanks and armored vehicles, reactive armor would not offer much protection from heavy missiles, but it could prove useful against waterborne IEDs, swarm attacks, and similar threats. Given its modular design, reactive armor could be installed and removed based on threat force-protection (FPCON) levels. The October 2000 attack on the USS Cole (DDG-67) resulted in 17 sailors killed and 37 wounded and a 40-foot hole in her side following the detonation of C-4 explosives.8 Reactive armor could limit damage in similar attacks by directing energy away from the hull.

Ceramics. Like reactive armor, ceramics could be add-on armor. Ceramic-polymer composites are much lighter than steel, an important factor in naval architecture. Applying ceramics to interior spaces or top-side compartments could protect against fragmentation caused by larger strikes. Debris caused by an explosion can increase an initial strike’s lethality.

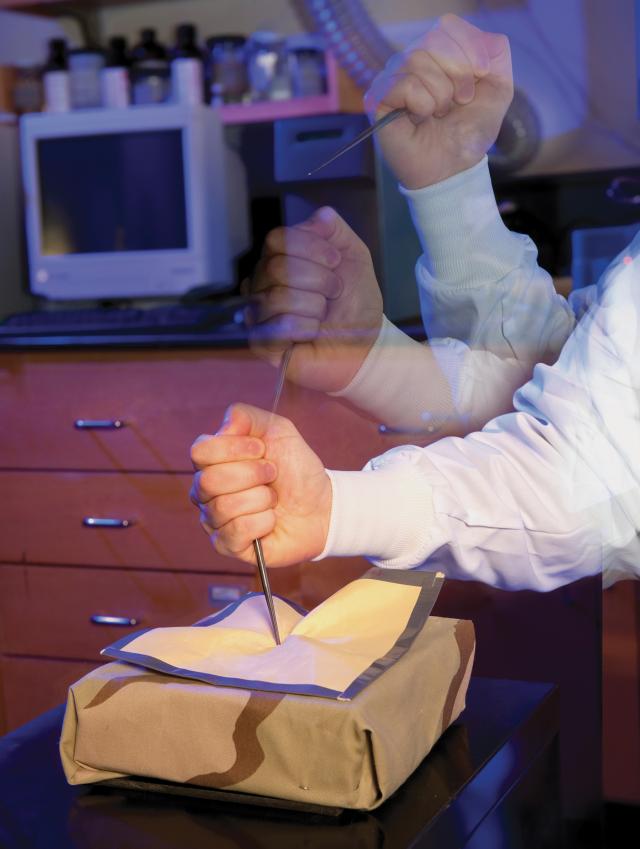

Fabrics. Armored fabrics also can reduce the effects of fragmentation. Synthetic fabrics such as Kevlar have long been used by militaries for protecting personnel. In the future, such fabrics could be applied to the surface of or layered within interior walls and bulkheads, potentially reducing structural distortion and limiting a strike’s depth of penetration.

Liquids. Shear-thickening fluids (STFs) are “non-Newtonian” fluids—fluids that change viscosity under the application of force. Depending on the force applied to them, STFs can act like a liquid or a solid. STF technologies have disrupted the body armor industry in recent years. When compared with plain Kevlar, STFs offer another advantage. In general, STF-impregnated Kevlar weighs less, because it requires fewer layers to achieve the same protection.9 Weight and weight distribution are critical matters in naval architecture. STFs could protect critical compartmented spaces to reduced casualties from fragmentation and shrapnel.

Each of these technologies has the potential to disrupt the status quo. The traditional model of providing armor primarily to external surfaces of combatants should be rethought. The potential for synergistic protection—in which the sum of the fortifications equates to safety beyond each armor’s individual value—occurs when advancements are applied together.

Consider the case of the USS Stark (FFG-31). On 17 May 1987, an Iraqi fighter fired two Exocet missiles, both striking the ship.10 Thirty-seven sailors were killed, but thanks to the crew’s heroic damage-control efforts, the casualties were less than they might have been, and the ship was saved from sinking. Although the first of the two missiles did not detonate, it continued through several of the ship’s frames, releasing fuel and kinetic force deep inside the hull. Internal armor technologies on a future ship attacked by Exocet-like missiles might prevent a missile (dud or otherwise) from penetrating so far, containing the damage in a smaller area.

It Has to Float to Fight

Five years have passed since the Navy began the conversation about “distributed lethality” under the notion that “if it floats, it fights.” Simply put, the concept argues that “for more power in more places, the Navy should increase the offensive might of the surface force and employ ships in dispersed formations.”11 Former Chief of Naval Operations Admiral John Richardson’s A Design for Maintaining Maritime Superiority Version 2.0 called for continuing to mature the concept as distributed maritime operations.12 These operations enable “localized sea control to generate larger combat effects through increasing the offensive power.”13 But if a combatant that fails to float necessarily fails to fight, then ensuring adequate physical armor is paramount, especially when operating geographically dispersed, isolated from friendly ships and shores—and mutual defense.

Violent conflict with China, Russia, or some other adversary may not be imminent. But the Navy must be prepared for it if such a conflict arrives. The Navy will need a variety of superior and innovative defenses—including armor—to absorb the first strike, stay in the fight, and see the battle through to victory.

1. Missile Defense Advocacy Alliance,“YJ-18,” 2020.

2. “USS Phoenix (CL-46),” NavSource Online: Cruiser Photo Archive.

3. “BB-38 USS Pennsylvania,” NavSource Online: Battleship Photo Archive.

4. The other three were the USS Honolulu (CL-48) at the Battle of Leyte Gulf; the St. Louis (CL-49) at the Battle of Kolombangara; and the Helena (CL-50) at the Battle of Kula Gulf. Strafford Morss, “Battleships—Vulnerable Anachronism?” Warship International 21, no. 2 (1984): 211–21.

5. Robert G. Albion, “Review of The Introduction of the Ironclad Warship,” The Journal of Modern History 6, no. 2 (1934): 207–9.

6. Carolyn Bonner and Kit Bonner, USS Missouri at War (Zenith Press, 2008).

7. Ronald O’Rourke, Navy Frigate (FFG[X]) Program: Background and Issues for Congress, Congressional Research Service, 20 December 2019.

8. Robert Burns, “Persian Gulf Security Increased,” Associated Press, 5 December 2000.

9. “Liquid-Filled Body Armour Relies on Shear-Thickening Fluids,” New Materials International, 23 January 2013.

10. U.S. Navy, “Final Report: Attack on USS Stark (FFG-31),” 17 May 1987.

11. VADM Thomas Rowden, RADM Peter Gumataotao, and RADM Peter Fanta, USN, “Distributed Lethality,” U.S. Naval Institute Proceedings 141, no. 1 (January 2015).

12. ADM John M. Richardson, USN, A Design for Maintaining Maritime Superiority Version 2.0 (U.S. Navy, December 2018).

13. Paul Beery, “Distributed Maritime Operations” Naval Postgraduate School wiki, 6 November 2018.