Imagine several hazmat suit–clad figures in a room monitoring what appear to be stacks of computer servers connected by a web of tubing. A colorless liquid begins to flow out of the final tube and into a storage container. One individual in the room turns and nods to the observation window, confirming the successful resumption of Syria’s chemical weapons program.

Or, picture elsewhere a cohort of U.S. Marines, who just received artillery fire near a village. The warfighters and several local individuals see and smell gas. A small swarm of drones deploys to collect air samples as the Marines simultaneously sample their blood on tiny disposable papers that resemble computer chips to test for exposure to a toxic chemical. The drones quickly relay to the warfighters that sulfur mustard agent was released in the area.

As these hypothetical but plausible stories illustrate, actors good and bad might soon take advantage of microfluidics technology to produce or defend against chemical weapons. This technology has significant implications.

Microfluidics technology enables greater efficiency and control for some chemical reactions than traditional chemical equipment. Microfluidic devices are already being used in the chemical, medical, and pharmaceutical industries. The technology is widespread but also rapidly developing, with significant uncertainties around its future potential, and the security policy implications have not received enough attention. Microfluidics technology could enable nefarious actors to produce chemical and biological weapons—but can also enable efforts to defend against such threats.

Various elements of the Department of Defense (DOD) science and engineering community have investigated and invested in programs focused on microfluidics technology. But the rapid maturation and diffusion of microfluidics technology—and its relative lack of awareness or visible discussion among nonproliferation and counterproliferation experts—leaves the United States at risk of either surprise or misuse of the technology by adversaries. DOD must grapple with and catalyze dialogue on the implications of microfluidics technology for today and tomorrow.

Microfluidics Explained

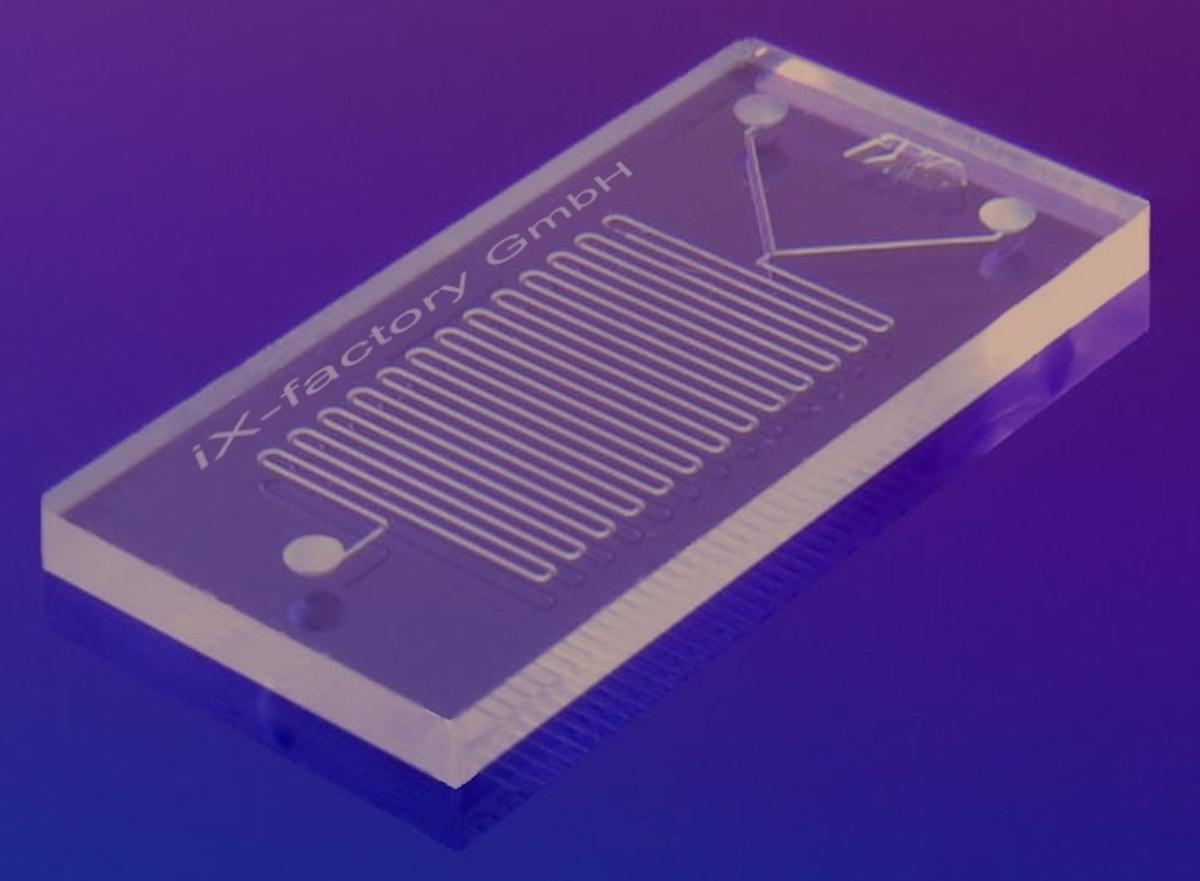

Microfluidics is chip-scale chemistry involving the study and manipulation of small quantities of fluids, at or below the microliter (1/1000th of a milliliter) level. Microfluidic devices, such as microreactors, flow fluids within very small spaces, typically in channels less than one millimeter across, often as small as a few dozen or hundred micrometers, or less than 1/10th the diameter of a human hair.

Microreactors and similar devices were inspired by and conceptually modeled after silicon microchips. Their design—sometimes called “lab on a chip”—can best be understood by imagining a simple circuit board, in which electricity flows along small copper channels that interact with the electric components attached to the circuit board’s base. In a microreactor, fluids flow through tiny tubes and interact in mixing areas. Small, precise pumps attached to the microreactor send chemicals into those tubes and pump them out. Computer systems connected to the devices regulate these flows.

Microreactor devices allow chemical processing with greater efficiency, control, and automation than traditional equipment for some organic chemical reactions. The geometries of microreactors and their small size change the flow dynamics and mix compared to larger-batch chemical systems.1 Fluids flow alongside each other in a laminar rather than turbulent manner. This dynamic allows more efficient and more-controlled heating and mixing of fluids.2 As a result, fluids can be continuously pumped and controlled with high precision in microreactors, rather than processed in batches. Microreactors enable the production of very pure substances, while reducing the inputs needed and the waste produced.3 They can reduce the number of steps taken to process chemicals within batches. Notionally, they should be able to shorten significantly the time needed for a given chemical reaction, and increase the total yield and purity of the product.

Microfluidics technology is widespread and its accessibility and global diffusion are rapidly increasing as convergent emerging technologies continue to mature. Germany, which paved the road for microfluidics research and development in the 1980s, is now accompanied by the United States, Japan, and—most recently—China in the number of microfluidics patents.4 Other nations are gaining ground, including Canada, France, India, Italy, Mexico, the Netherlands, South Korea, Switzerland, and the United Kingdom.5 Over 280 microfluidic vendors exist internationally, and demand for microfluidics technology is projected to surge within the next five years.6

Potential applications of chip-scale chemistry are many, and improvements in manufacturing have made microreactors cheaper, more diverse, and sometimes more accessible. Existing devices range from cheap and accessible paper-based, plastic or wax-coated devices costing less than $50, to sophisticated devices costing thousands.7

Microreactors may remain unsuitable for some organic chemical reactions in the long term because they do not work for many types of complex chemical reactions.8 The vast majority of devices handle complex chemical synthesis or hazardous reactions that demand chemical expertise and expense beyond what is needed for traditional bench or industrial-scale chemistry.9 However, advances in related emerging technologies such as additive manufacturing are trending to mitigate or bypass some of these hurdles, especially the fabrication of the devices with new materials.10

Emerging microfluidics technology thus enables chemistry either not feasible in other ways, or feasible but more expensive or slow through other methods. Microfluidics devices also take up less space, making them potentially far more mobile than traditional chemical equipment. This has implications for those who wish to obtain chemical and biological weapons and those who must defend against them.

WMD Implications

Microfluidics technology can contribute to the proliferation of chemical and biological weapons in the near and medium terms. The greater efficiencies, as well as reduced footprint and hazard, offered by microreactors may enable the study or production of chemical and biological weapons-related materials among nefarious actors, although it is unlikely a non-state actor would be capable or motivated to field microreactors in the immediate future. However, more turn-key capabilities are likely to develop in the future and could potentially make microreactors more accessible for malign use by non-state actors.

In addition, microfluidic devices are accessible to some state-supporters or -sponsors of terrorism. Countries could use microreactors to establish clandestine chemical weapons research and production facilities and synthesize known or novel chemical agents, although some traditional chemical equipment would still be needed to purify or separate products through different steps of chemical agent synthesis.11 However, the design and size of microfluidic devices make weapons development facilities easier to disguise and hide from monitoring and surveillance.12

And although only 25 percent of known reactions related to chemical weapons agents (CWAs) can be sustained in microreactors without damaging or destroying the device, the devices can synthesize quite a few known CWAs, including sulfur mustard blister agent.13 These devices could also unlock more efficient techniques for back-integration of unregulated chemicals to produce known CWAs, or even novel agents. Intelligence services and multilateral regimes would likely miss signs of production of the latter.14

In a similar vein, states could misuse microfluidics technology along with biological synthesis techniques and technologies for biological weapons research and development. Experts in biological weapons generally concur that nefarious actors are unlikely to synthesize novel pathogens and that a more viable option would be recreating known dangerous viruses.15 They assess that the primary threat of misuse of biological technology and techniques rests in state-level biological warfare programs.16

States can integrate microfluidics technology in campaigns using other emerging biological technologies to expedite research on biological vulnerabilities and create opportunities for weaponization. Emerging biological tools and techniques are increasingly converging with microfluidics technology.17 Genome-editing and genetic screening are exposing genetic vulnerabilities, and microfluidics technology can enhance such research.18 Microreactors could make the study of potentially lethal pathogens not only more cost-effective, but also quicker and better concealed.19

Defensive Implications for Chemical and Biological Weapons

Fortunately, no available evidence indicates that states have sought to enlist microfluidics technology for chemical or biological weapons development, and DOD has engaged in considerable research and development to counter adversarial threats and enhance warfighter capabilities in this area. DOD is in a unique position to capitalize on advances in microfluidics technology to defend against chemical and biological weapons and increase the lethality of the joint force.

Microreactors could be used to rapidly detect and identify chemical and biological weapons agents anywhere they might be used. The small size of these devices could enable development of quick, efficient, and portable detection systems.20 In the 1990s, the Defense Advanced Research Projects Agency (DARPA) aimed to develop field-deployable microfluidic equipment to detect chemical or biological warfare agents.21 Since then, DOD has made notable strides in integrating microfluidics technology in sensor platforms to defend the warfighter. The Naval Research Laboratory (NRL) demonstrated use of microfluidics technology within autonomous underwater vehicles to detect explosives.22 The small size and increased sensitivity of this technology may allow it to one day be mounted on swarming drones to perform rapid CWA detection and improve upon the capabilities of the ScanEagle unmanned aerial system.23

Microfluidics technology also offers enhanced opportunities in point-of-care diagnostics, and can be used to study and defend against biological threats. Portable microfluidics-based kits are able to detect pathogens rapidly.24 Microreactors also are being developed into organ-mimicking devices for synthetic biological studies,25 which allow a greater degree of observation and data gathering.26 Advances in these studies will almost certainly improve understanding of cellular responses to afflictions, and consequently unlock pathways to develop countermeasures for biological and chemical warfare agents.

Microfluidics on a Macro Scale

Despite the volume of investigation of and investment in microfluidics by the United States, the rapid maturation and diffusion of microfluidics technology coupled with the relative lack of awareness or visible discussion among nonproliferation and counterproliferation experts leaves the nation at risk of either adversarial technology surprise or misuse. Adversaries, such as China and Iran, which endeavor to degrade U.S. and allied capabilities and counter U.S. interests, have invested significantly in research and development of microfluidics systems.

The Department of Defense must seek broader awareness of this technology and should enhance collaboration across the various agencies and companies who are affected by and/or have the ability to shape emerging microfluidics technology especially in research for defense against weapons of mass destruction.

1. George M. Whitesides, “The origins and future of microfluidics,” Nature 442 (2006), 368.

2. Douglas P. Holmes, “Confined Fluid Flow: Microfluidics and Capillarity,” Boston University (2015).

3. Katherine S. Elvira, Xavier Casadevall i Solvas, Robert C. R. Wootton, and Andrew J. deMello, “The Past, Present, and Potential for Microfluidic Reactor Technology in Chemical Synthesis,” Nature Chemistry 5 (2013), 905–906.

4. Volker Hessel, Christoph Knobloch, and Holger Löwe, “Review on Patents in Microreactor and Micro Process Engineering,” Recent Patents in Chemical Engineering 1:1 (2008), 1–14. Cited in: Amy E. Smithson, “Chemical Micro Process Devices,” Innovation, Dual Use, and Security: Managing the Risks of Emerging Biological and Chemical Technologies (Cambridge, Massachusetts: The MIT Press, 2012), 237.

5. Microfluidics: A Global Market Overview, (Hyderabad, India: Industry Experts, April 2018), 1–5.

6. “List of Microfluidics, Lab-on-a-Chip, and BioMEMS Companies,” FluidicMEMS (6 February 2016); “Global Demand for Microfluidics Markets is Set to Reach US$4.2 Billion in 2018,” Industry Experts Incorporated, 20 April 2018.

7. Kentaro Yamada, Terence G. Henares, Koji Suzuki, and Daniel Citterio, “Paper-Based Inkjet-Printed Microfluidic Analytical Devices,” Angewandte Chemie International Edition 54:18 (13 April 2015); Hitoshi Asano and Yukihide Shiraishi, “Development of Paper-Based Microfluidic Analytical Device for Iron Assay Using Photomask Printed with 3D Printer for Fabrication of Hydrophilic and Hydrophobic Zones on Paper by Photolithography,” Analytica Chimica Acta 883 (9 July 2015), 55–60; Emanuel Carrilho, Andres W. Martinez, and George M. Whitesides, “Understanding Wax Printing: A Simple Micropatterning Process for Paper-Based Microfluidics,” Analytical Chemistry 81:16 (15 July 2009), 7091–7095.

8. “Technologies as More Sustainable Alternatives to Batch Processing,” Chemical Innovation: Technologies to Make Processes and Products More Sustainable, GAO-18-307, United States Government Accountability Office: Center for Science, Technology, and Engineering (February 2018), 72.

9. Daniel T. Chiu, Andrew J. deMello, Dino Di Carlo, Patrick S. Doyle, Carl Hansen, Richard M. Maceiczyk, and Robert C.R. Wootton, “Small but Perfectly Formed? Successes, Challenges, and Opportunities for Microfluidics in the Chemical and Biological Sciences,” Chem 2 (9 February 2017), 201–223; Christian Holtze, Sebastian A. Weisse, and Marcel Vranceanu, “Commercial Value and Challenges of Drop-Based Microfluidic Screening Platforms – An Opinion,” Micromachines 8:193 (June 20, 2017), 1–13.

10. Robert B. Channon, Maxim B. Joseph, and Julie V. Macpherson, “Additive Manufacturing for Electrochemical (Micro)Fluidic Platforms,” Interface (Spring 2016), 63–68.

11. Natasha Bajema, “Emergence and Convergence Risk Assessment Survey: Subject Matter Expert Survey Results Analysis,” National Defense University (2018), 23–24.

12. Elvira, Casadevall i Solvas, Wootton, and deMello, “The Past, Present, and Potential for Microfluidic Reactor Technology in Chemical Synthesis,” 905–906.

13. Andreas Zaugg, Julien Ducry, and Christophe Curty, “Microreactor Technology in Warfare Agent Chemistry,” Military Medical Science Letters 82:2 (2013), 63–68.

14. Parshall, Pearson, Inch, and Becker, “Impact of Scientific Developments on the Chemical Weapons Convention (IUPAC Technical Report),” 2330–2333.

15. Jonathan B. Tucker and Raymond A. Zilinskas, “The Promise and Perils of Synthetic Biology,” New Atlantis 25 (Spring 2008), 38. Cited in: Filippa Lentzos and Pamela Silver, “Synthesis of Viral Genomes,” Innovation, Dual Use, and Security: Managing the Risks of Emerging Biological and Chemical Technologies (Cambridge, Mass.: The MIT Press, 2012), 136.

16. Ibid, 136–139.

17. Jason A. Reuter, Damek Spacek, and Michael P. Snyder, “High-Throughput Sequencing Technologies,” Molecular Cell 58:4 (May 21, 2015), 586–597.

18. Xin Han, Zongbin Liu, Li Zhao, Feng Wang, Yang Yu, Jianhua Yang, Rui Chen, and Lidong Qin, “Microfluidic Cell Deformability Assay for Rapid and Efficient Kinase Screening with the CRISPR-Cas9 System,” Angewandte Chemie International Edition 55 (2016), 8561–8565.

19. Paul Datlinger, André F. Rendeiro, Christian Schmidl, Thomas Krausgruber, Peter Traxler, Johanna Klughammer, Linda C. Schuster, Amelie Kuchler, Donat Alpar, and Christoph Bock, “Pooled CRISPR Screening with Single-Cell Transcriptome Readout,” Nature Methods 14 (January 18, 2017), 297–301.

20. Parshall, Pearson, Inch, and Becker, “Impact of Scientific Developments on the Chemical Weapons Convention (IUPAC Technical Report),” 2334–2339.

21. Whitesides, “The origins and future of microfluidics,” 368.

22. A. A. Adams, P. T. Charles, J. R. Deschamps, and A. W. Kusterbeck, “REMUS100 AUV with an Integrated Microfluidic System for Explosives Detection,” National Research Laboratory Review, United States Navy (2011).

23. Ibid, 58. See also Zachary Kallenborn and Philipp C. Bleek, “Swarming Destruction: CBRN Implications of Emerging Drone Technology” The Nonproliferation Review (January 2019).

24. Ibid, 2–3, 5.

25. Jo Best, “Organs on Chips: The DARPA-Backed Project Mimicking the Human Body on a Tiny Scale,” ZDNet (May 12, 2016); Gregory Linshiz, Erik Jensen, Nina Stawski, Changhao Bi, Nick Elsbree, Hong Jiao, Jungkyu Kim, Richard Mathies, Jay D. Keasling, and Nathan J. Hillson, “End-to-End Automated Microfluidic Platform for Synthetic Biology: From Design to Functional Analysis,” Journal of Biological Engineering 10:3 (2016), 1–15.

26. Rimantas Kodzius, Frank Schulze, Xinghua Gao, and Marlon R. Schneider, “Organ-on-Chip Technology: Current State and Future Developments,” Genes (Basel) 8:10 (2017), 266–279.