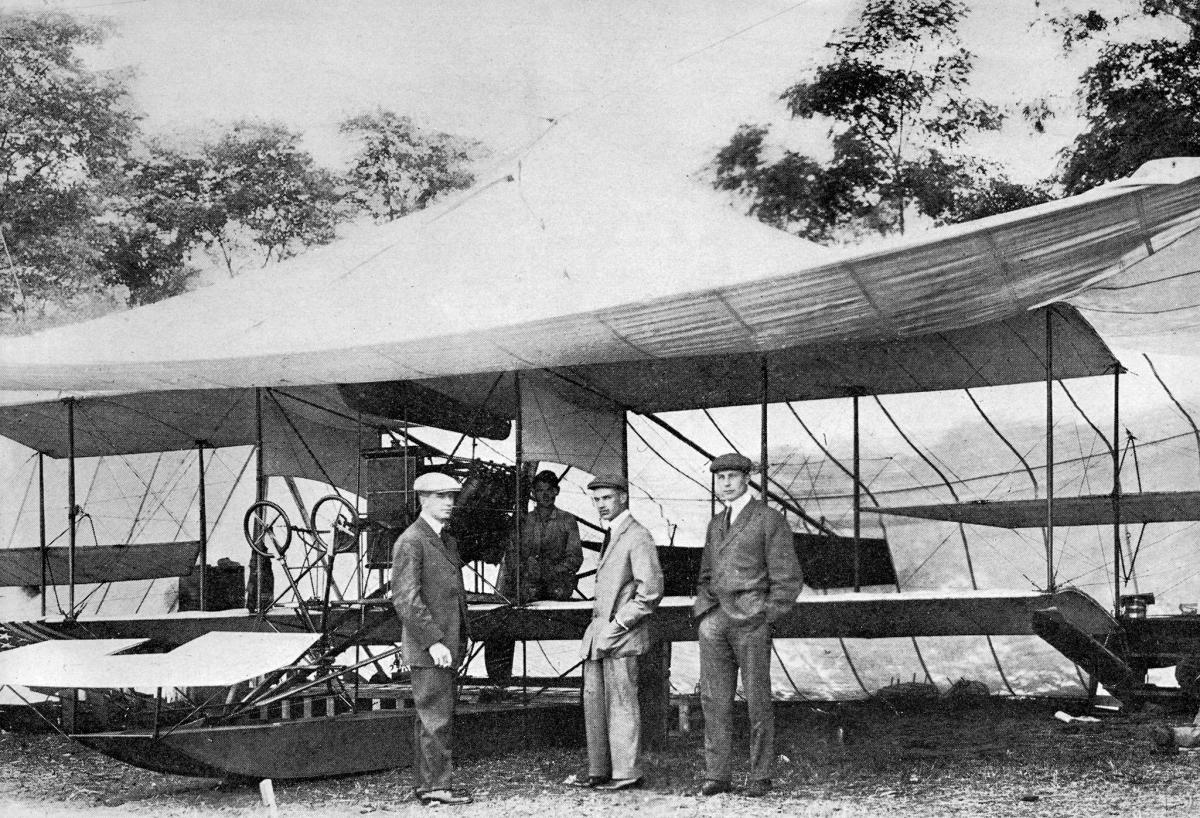

Part I of Mr. Ray's three-part article about the dawn of naval aviation appeared in January 1971, the 60th anniversary year of the events discussed. "Naval Aviation: The Beginning" concluded at the point where the Navy agreed to purchase two Curtiss airplanes and one Wright plane. This, then, is Part II, the story of the Navy's first three aircraft and of the three men chosen to fly them.

Theodore Gordon Ellyson was born in Richmond, Virginia, in 1885, and graduated from the Naval Academy in 1905. He was commissioned ensign in 1907 after serving two years as a midshipman (as required by law at that time) and was promoted to lieutenant in September 1910.

Lieutenant Ellyson's first solo flight was made in public on the Sunday afternoon of 29 January 1911. He had already undergone a good deal of training at Glenn Curtiss' North Island, California, school. The Curtiss Company was performing at the San Diego Aerial Meet held by the Aero Club of San Diego at the country club grounds and Ellyson participated in one event.

Beginning in January 1911, Ellyson underwent a rigorous training program at Curtiss' North Island School where he spent as much as 12 hours each day in training. He received aircraft maintenance training in the middle part of each work day, during which he learned to repair, assemble, and construct aircraft engines, fuselages, and other component parts. Unlike many of the students who wanted to rush into flying instructions, Ellyson regarded it more important to master aircraft maintenance first.

The earliest part of the morning was reserved for flight training since the air currents were least turbulent after sunrise. Aircraft flight training was a slow, graduated process which began with familiarization of the controls. During the next phase, each trainee taxied alone at 20 to 25 miles-per-hour the length of a half-mile course in a low-powered, single-place Curtiss biplane known as "Lizzy." When Lizzy was taxied to the end of the half-mile course, she was turned around by another student so the trainee operator could make his return trip. This stage of instruction was dubbed "grass cutting," because the propeller actually thrashed the tall grasses of the field.

As each student went through his cycle of grass cutting, the other students anxiously awaited his finish. For, if Lizzy was damaged, all further training stopped until repairs were made.

Dreading such forced suspensions in their training, Ellyson and civilian student C. C. Witmer furtively visited the North Island aerodrome shortly after sunrise day after day. Before the other trainees arrived, they would start Lizzy and secretly make their practice runs over the field. Thus, they were assured of receiving the day's practice without having their training impeded by the mishaps of the others.

After a few days of grass cutting, thereby becoming accustomed to the controls of the airplane, students were permitted more control over Lizzy. Another propeller, one that had some lifting power, was fitted to the biplane, and the throttle was increased to full power. The students next made brief straight hops into the air from 20 to 50 feet in length but not more than a few feet off the ground. Again Lizzy was turned around at the end of each short flight so the trainee could complete his circuit with short return jumps through the air.

Upon completion of the grass cutting phase, each student was taken aloft as a passenger in the Curtiss two-place hydroplane. First, the student experienced skimming on the water at 40 m.p.h. while the instructor steered. This was followed by short skips from the water executed by the instructor, followed by several days of hops up to 100 feet above the water.

The next phase in the flight training involved sustained flights of up to 50 m.p.h. in the Triad. Gradually, the students were instructed in how to make right and left half-circles, full circles, take-offs, landings, figure eights, altitude flights, and landings from glides.

When a flier wished to make a turn in a Curtiss-type airplane, he simply turned a steering wheel mounted on a control post in front of him in the direction of the desired turn. The steering wheel controlled a vertical rudder hinged in the tail assembly of the airplane and banked the plane for the turn.

To resume level flight, the pilot leaned opposite the turn toward the high side of the plane, as he naturally would to compensate for his loss of balance. This lateral movement of the pilot shifted a movable pair of braces situated on either side of the pilot's shoulders. The braces or shoulder yoke actuated two small ailerons suspended midway between the rear edges of the two wing tips. The ailerons were hinged and interconnected by wires so that one aileron flipped up when the other flipped down. The operation of the two ailerons restored the airplane to straight and level flight. Considerable effort was required by the pilot, though, to force the ailerons to operate.

The control post to which the steering wheel was affixed also moved fore and aft for depressing, leveling, or raising two hinged horizontal elevators simultaneously: one horizontal elevator made up part of the rear tail assembly; the other was situated ahead of the pilot's seat. These concurrent motions of the two horizontal elevators caused the airplane to descend, fly horizontally, or ascend, respectively. In addition, Curtiss airplanes were equipped with pedals for throttle and wheel brake control.

Operating from the water in a Curtiss pusher hydroplane was slightly different from operating a Curtiss land plane. There were those who argued that water plane flying was much safer than land plane flying, since hydroplanes, unlike certain land planes, could never become airborne if underpowered, because of the sucking action of the water on the hydroplane's floats. It actually took more power to break free of the water's grasp and arise from the water than was necessary to make a safe flight.

Now that spring had arrived, the Curtiss Company prepared to return to its regular camp at Hammondsport, New York. The three Army students being trained by the Curtiss Company were ordered by the War Department to report to Fort Sam Houston, Texas, to fly scouting missions along the U. S.-Mexican border. Ellyson, on the other hand, was invited by Curtiss to return with the Company to Hammondsport, so that he could master flying the Triad-type hydroplane as well as the wheel-equipped Curtiss land planes.

In April, the Curtiss Company and several pupilsreturned to Curtiss' regular camp on LakeKeuka adjacent to the aircraft factory at Hammondsport. Ellyson reported to Washington in April, then joined the Curtiss Company at Hammondsport to continue experiments and to practice further training. In addition to his postgraduate flying instruction, Ellyson was ordered to serve as naval inspector of the Curtiss airplanes under construction for the Navy.

Meanwhile, the Navy Department selected Lieutenant John Rodgers as the officer to take flight instruction at a Wright Company camp. Lieutenant Rodgers, together with an enlisted mechanic, was ordered to report to the Wright's Aviation Training Camp at Simms Station, Dayton, Ohio, to "confer with the Wright Brothers at that place for instruction in the an of aviation."

Four years older than Ellyson, Rodgers was a descendant of a family of high-ranking naval officers dating back to the Barbary Wars. Rodgers had graduated from the U. S. Naval Academy in 1903 and had received his promotion to lieutenant in 1908.

Rodgers had made a solo aerial flight months before he began training at the Wright camp. In January 1911, he had been lifted 400 feet in the air on 11 man-lifting kites designed by Samuel F. Perkins. The huge Perkins box kites, supporting Rodgers seated in a "boatswain's chair," were sailed from the stern of the cruiser USS Pennsylvania in San Francisco Harbor, as she steamed at 12 knots into an B-knot wind. Rodgers had made observations for 15 minutes, sighted ships as far as 40 miles away, then had signaled his findings to the officers below.

The day Rodgers arrived at Dayton, 17 March 1911, he received eight flying lessons, and during the last two lessons he manipulated the controls himself. Since Wright machines, unlike the Curtiss training machines, were two-place airplanes, an instructor could accompany each student until he was prepared to solo. Thus, the long painstaking process of grass cutting in a single-place airplane was bypassed. And, if good weather prevailed for any length of time, a Wright student could learn to fly in one week's time.

The first flights of a Wright trainee were of but four or five minutes duration. Gradually, the lessons reached a duration of about 15 minutes each. By 10 April, after two weeks of practice flights, and despite damp, coldpenetrating winds, Rodgers had learned to operate the controls fairly competently. Then he concentrated on making practice landings.

The Wright B-1 type biplane was operated by warping the wings and positioning the rudder in the tail assembly simultaneously. Both actions were controlled by a single vertical wing-warping and rudder control stick (or lever) situated between the two pilots' seats. The wing-warping and rudder control stick banked the Wright plane left when pushed forward, by raising the right wing, depressing the left, and turning the rudder to the left. Conversely, when the wing-warping stick was pulled backward, the plane was banked to the right. If additional rudder control was needed to make a sharper turn than usual, or to prevent skidding or sliding, the operator simplymoved a handle hinged at the top of the wing-warping and rudder control stick in the direction of the turn to create a correspondingly greater turn in the vertical tail rudder.

The rear horizontal elevators of the Wright machine were controlled by one of two vertical sticks located on the outer side of the two pilots' seats. The elevator stick nosed the plane downward when pushed forward and upward when pulled back. When banking for turns, the elevator lever was pulled back to compensate for any loss of altitude; the angle of a piece of string dangling freely indicated whether or not the turn was too steep for safety. Generally, the elevator stick as well as the wing-warping and rudder control stick had to be manipulated continuously to maintain level flight. A pedal connected to the magneto controlled the power output during each flight.

Since the Wright plane had only the one wing-warping and rudder control lever between the two pilots' seats, each Wright pilot learned to steer the plane with either his right or his left hand, depending on which of the two seats he occupied during his training period. Each Wright pilot, therefore, became a left or a right seat pilot.

The Wright and Curtiss systems of aircraft control were so radically different that it was not practical to expect anyone Navy pilot to master them both. Then Curtiss-trained Ellyson tried to fly the Navy Wright B-1, piloted by Rodgers, later in the year he was quite dismayed by what ensued:

He [Rodgers] turned the controls over to me and it was the queerest experience I have ever gone through. Of course he had to grab them every minute or two, but I got some practice. When the machine would tilt I would instinctively go through the same motions I would in a Curtiss and at the same time try to remember what to do in the Wright.

Each pilot characteristically favored the system of control with which he had learned to fly and was prejudiced against learning any other-which is completely understandable to later generations of aviators.

Rodgers practiced as much as he could whenever the April weather permitted. By 21 April, he was ready to make his first solo flight. He took off alone, circled the training field,flew above a field adjacent to the Simms Station training field, and returned and landed without incident.

In early May, several civilians, and Army Lieutenants Henry "Hap" Arnold and Thomas DeWitt Milling joined Rodgers to receive flying instructions at the Dayton flying school. Rodgers remained at the Wright Camp to practice emergency landings (gliding from altitudes of 100 to 500 feet with the engine throttled down) and to serve as official inspector of the Wright B-1 airplane which was being constructed for the Navy Department.

The Navy Department's procurement of three airplanes had been made contingent on the training of one naval aviator and one enlisted mechanic for each plane purchased. Rodgers and one mechanic were at Dayton obtaining instructions from the Wright Company for the B-1 purchased; Ellyson was at Hammondsport receiving added instruction from the Curtiss Company for the A-1 purchased. The Navy was eligible to have still another officer and two mechanics trained by the Curtiss Company for the A-2. Lieutenant (j.g.) John Henry Towers and two mechanics were selected and ordered to report to Hammondsport for training. Towers arrived on 27 June.

John Towers had been born in Rome, Georgia, in 1885. He graduated from the Naval Academy in 1906 and was promoted to lieutenant in July 1911. As a result of the instruction he received from Ellyson, Towers was able to make hops the length of the Hammondsport field by mid-July.

In addition to teaching Towers to fly, Ellyson flew hydroplanes and participated with Curtiss in exhibition flights during May at Bridgeport, Connecticut, and during June at both Cedar Point, Ohio, and Fail River, Massachusetts. He also inspected the development of the new Curtiss hydroplane A-I Triad and land-plane A-2, which were to become two of the Navy's first three airplanes.

Certain difficulties encountered by the Curtiss Company when building the A-1 and A-2 airplanes for the Navy and the somewhat unusual nature of one aspect of the problems was described by Towers:

Work was being pushed forward on the Navy aeroplanes when I arrived. So far as I know, there were never any actual plans for these. In some respects they were to be similar to planes already built, also with no plans. In other respects they were to be different. The workmen were supposed to remember how the earlier planes were built, but the differences were in the heads of Glenn Curtiss and Henry Kleckler, his shop foreman.

The white walls of the shop were covered with sketches made by Curtiss and Kleckler for the benefit of the workmen. This seemed to answer the purpose remarkably well until a new hand…whitewashed right over all the sketches…[and] delayed completion of the first plane [A-1 Triad] about two weeks, for nobody, not even Curtiss, could reproduce the sketches.

The white walls containing sketches were known as Curtiss' "Master Spare Parts Pattern Plan," since on them were traced the outlines of component parts of Curtiss aircraft sold, together with the names of the pilots who brought them. When a buyer damaged his aircraft and wrote to Hammondsport for replacement parts, the wall sketches of the parts served as the one reference source from which new spare parts could be reproduced.

The A-1 Triad was one of approximately 25 aircraft constructed by the Curtiss Company during 1911. It was a biplane, pusher-type amphibian that was completed for testing by June 1911. It was powered by a 50-h.p. Curtiss engine until 7 July when a 75-h.p. pusher-type V-8 engine, especially designed for it was completed and installed. The A-1 cost the Navy $5,500; it weighed approximately 1,200 pounds including gasoline, oil, and water. It could carry two men weighing up to 350 pounds, and could fly between 45 and 60 m.p.h.

The front horizontal elevator of the A-1 was situated about one-and-one-half feet above the prow of the pontoon and leading edge of the biwings. This front elevator was operated in conjunction with a rear horizontal elevator in the tail assembly. The rear elevator was positioned on either side of a vertical rudder that was situated about 13 feet behind the trailing edge of the biwings.

The two wings were covered by sailcloth coated with three applications of a rubberized compound. The wings were 28 feet, 8 inches long and 5 feet wide, and were spaced 5 feet apart. The two operators' seats and controls were directly forward of the leading edge of the lower wing and several feet behind the front horizontal elevator. Two separate, adjustable ailerons, about 3-by-11 feet in size, were suspended midway between the trailing edges of the biwing tips. They were hinged to operate up or down, in conjunction w.ith the left or right-hand motion of the shoulder yokes.

The A-1 was equipped with a dual-control system developed with the aid of Ellyson and Towers. The steering wheel was hinged on the control post so it could be shifted and locked in front of either of the two operators' seats. In addition, two pairs of shoulder yokes were provided so either pilot could operate the ailerons.

The main pontoon beneath the fuselage of the A-1 was sled-shaped, like the pontoon on Curtiss' earlier hydroplane with which he had made his air-to-water-to-ship demonstration flight in February 1911. The pontoon stretched to a length of 16 feet and a width of almost two feet. It was slightly over one-foot deep, most of which was submerged when the A-1 was at rest on the water. A pair of retractable landing wheels straddled either side of the pontoon. Beneath each of the two bottom wing tips was hung a small float to prevent the wings from striking the water. They were cylindrically-shaped, about five feet long, and were cone-tipped at either end.

The pusher-type V-8 engine installed in July was cradled between the central portions of the biwings and behind the two operators' seats. It weighed 290 pounds including magneto, carburetor, water pipes, and fittings. It turned between 1,050 and 1,250 r.p.m. and it developed 75 h.p. The cylinders had a 4-inch bore and a 5-inch stroke. The original 7-foot, 6-inch propeller was replaced by one of 7-foot, 8-inch length that developed 490 pounds of thrust. The gasoline tank held as much as 15 gallons of high octane gasoline, and the oil tank reservoir contained up to 3.5 gallons of oil.

Trial flights of the A-1 took place on 1 and 2 July, with Captain Chambers present to witness them. Curtiss was the first to test-fly the new A-1when, on July 1, he test-flew it five minutes at approximately 25 feet altitude. He found that it was satisfactorily balanced both on the water and in the air. Curtiss then piloted Ellyson for five minutes to test the A-l 'S balance with two persons aboard. The balance with the additional weight also checked out satisfactorily. Ellyson next made two solo flights in the A-1 to qualify for his pilot's license. The criteria to qualify for a pilot's license were the same as those prescribed by the Federation Aeronautique Internationale, which included flying two series of figure eights around two pylons or buoys, situated not more than 500 meters apart, for a distance of at least five kilometers on each test, and alighting within 50 meters of a predetermined marker both times. In addition, each candidate was required to ascend to an altitude of 50 meters (approximately 164 feet) or more above the starting point.

Ellyson flew a course of approximately ten miles laid out in the shape of the required figure eight. His first hop lasted 15 minutes and his second, 12 minutes; both were flown at about 300 feet altitude. He failed to qualify on his first attempt, however. The judges decided he had not received the proper instructions to fulfill the test adequately.

The following day Ellyson flew two hops over the same course for a total of 33 minutes. This time he successfully fulfilled the requirements for his pilot's license. He thereby acquired Aero Club of America license No. 28, Military Aviator's certificate No. 26, and Naval Aviator's certificate No. 1. Ellyson's was the first license ever awarded for flights made in a waterplane.

The following evening of Monday 3 July, Ellyson attempted to fly Captain Washington 1. Chambers to Penn Yan (on the other side of Lake Keuka) where Captain Chambers, coordinator of all naval aviation, was to board a train for his return trip to Washington. Lack of a wind, insufficient power from the underpowered 50-h.p. engine then in use, plus the weight of two people prevented the A-1 from getting off the water. Nevertheless, Ellyson ferried Chambers the 22 miles across the lake in the A-1. After discharging Chambers at his destination, Ellyson was able to arise from the water and fly the return trip. Darkness overtook him while en route to Hammondsport, however, and he was forced into making the Navy's first night landing, which he accomplished on his second try.

In mid-July, a couple of weeks after the first test flights of the A-1, Orville Wright flew the acceptance tests of the Navy Wright B-1 at Dayton, Ohio. Captain Chambers and Lieutenant Rodgers witnessed them.

The Wright B-1 was a two-place airplane weighing 1,250 pounds (including gasoline, oil, and two people); it had biwings 38 feet, 6 inches long; 6 feet, 6 inches wide; spaced 5 feet, 4 inches apart, and covered by a cloth produced by the Goodyear Tire and Rubber Company.

The horizontal elevator, comprising the rear appendage of the B-1, was about 13 feet behind the trailing edge of the biwings, and measured 15 feet, 2 inches long by 3 feet wide. The front third of the horizontal elevator remained stationary while the remaining two-thirds wasflexible for operation up or down. The vertical rudder was situated directly ahead of the elevator and measured 5 feet by 18 inches. Although the Navy's order called for a Wright two-place biplane equipped with pontoons for water flying, Captain Chambers was disappointed to find that "Wilbur Wright did not approve of water flying at that time and so failed to furnish pontoons." Hence, the Navy's B-1 came equipped with landing wheels and front skids like the regular Wright B-18 produced at this time. It was powered by a 4-cylinder vertical engine having a 4 3/8-inch bore and 4-inch stroke that developed between 30 and 40 h.p., turned at 1,325 r.p.m., and weighed between 180 and 200 pounds including accessories. This type of Wright engine enjoyed a reputation for reliability; nevertheless, the poppet valves of the one produced for the Navy proved troublesome. The engine was cradled between the biwings, right of center, and helped equalize the weight of the two operators seated left of center.

The radiator carried three gallons of water and the gasoline tank 12 gallons of gasoline. The engine actuated two pusher propellers by a chain drive. The propellers had a diameter of 8 feet, 6 inches, and revolved in opposite directions. They were geared to turn at a ratio of 11 revolutions for every 34 of the engine; and they developed a thrust of 250 pounds.

The B-1 had nickel-plated connections. Double warping wires were added as an extra measure of precaution after a warping wire of an earlier Wright plane had snapped during flight. Brand-new and never-before-flown, the Navy B-1 sparkled handsomely in the July sun as it was readied for its test flights. Orville took it aloft for its maiden flight. He climbed to 1,000 feet, flew close circles, figure eights, and short cross-country flights. He flew about one hour, alighted, then flew approximately one-half hour with Captain Chambers as passenger.

At the Curtiss Camp, meanwhile, Ellyson requested that the two Curtiss planes be retained at Hammondsport a longer time to make more test and trial flights. This found instant favor with the Navy Department which was embarrassed by having three new airplanes on hand and no place to keep them. Although the original contracts called for delivery of the planes in July, it was to be late September before construction of a Navy aerodrome was completed. Consequently, both Ellyson and Rodgers were granted permission to keep the A-1, A-2, and B-1 at Hammondsport and Dayton, respectively, until the Navy's aerodrome was established.

Major repairs were undertaken on the A-1's engine, radiator, retractable landing wheels, propeller, and fuselage at Hammondsport during the summer of 1911. After the 75-h.p. 8-cylinder Curtiss engine (originally designed for the A-1) was installed on the A-1 in July, Curtiss flew three test flights, one with Ellyson as passenger, to test its strength. The new engine checked out satisfactorily. The following day, the A-1's pontoon was shifted two inches forward to attain a better balance in relation to the new heavier engine, and a new gasoline tank was fitted over the engine. However, the position of the controls was so radically altered by these changes that the pilot was required to hold the controls forward in order to maintain balance. Accordingly, two more inches were added to a push rod leading from the control post in order to restore the controls to their former position.

On 10 July, with the retractable wheels extended for land operations, Curtiss flew the A-I from the ground. Curtiss manually retracted the wheels in flight with a foot pedal, and then alighted on the water. The wheels were damaged during the take-off from land, though; so they had to be removed for repair. Two days later, the pontoon itself was detached and landing wheels were fitted to the A-1's chassis. A hydro board was installed in front of the landing wheels and two tin pontoons were placed on either side of the engine to serve as flotation equipment in case the plane wasforced to alight on the lake. Several flights were made on 12 and 14 July, all but one of which were piloted by Ellyson. Passengers, including Lieutenant Towers as passenger-trainee, were taken aloft on nine hops piloted by Ellyson on the 14th.

During the last hop, however, two bearings burned out in the 75-h.p. engine. The engine was removed from the A-1 on the 18th and taken to the Curtiss factory for tests and repairs. On 21 July, the overhauled engine was reinstalled in the A-1, and the pontoon was reattached in place of the wheels. The retractable wheel assembly was discarded altogether because of its heavy weight. Another radiator replaced the original A-1 radiator that was damaged by vibration in flight.

The A-1’s engine, even after being overhauled, was far from perfect. Ellyson complained that during the rest of the summer at Hammondsport, the A-1’s engine “failed in so many respects that it had to be rebuilt.” Curtiss, incidentally, replaced each new part at his own expense.

Other difficulties plagued the A-1 as well. The wing tip floats tended to upset the plane when they became accidentally submerged, and water seepage in the main pontoon jeopardized the A-1’s balance. Modifications, repairs, innovations, and proposed experiments were threshed out at Mrs. Mott’s boarding house, where many of the aviators roomed.

But troubles with the A-1 continued to dog Ellyson for the rest of the summer. He cataloged certain of the faults he detected as follows:

The machine did not leave the water in a calm with the weight we thought necessary; in rough water we occasionally broke a propeller; if there were any sort of a sea, we would be wet to the knees, it was easy to make a bad landing especially in a side wind; it did not handle as well as we desired on the water, and it was not fitted with a self-starter.

Ellyson logged more than 50 individual flights as pilot of the A-1 Triad during the summer of 1911. The flights totaled slightly over 11 hours, making an average of 12 minutes per flight. He carried a passenger on more than half the flights, including Towers as student-passenger on nine of the flights.

During a training flight by Ellyson and Towers the night of 21 August, the A-1 crashed into Lake Keuka. The engine of the A-1 stopped suddenly at 200 feet, and the plane plunged into the water, where, Ellyson recalled, it “turned completely over so quickly that it carried us down with it.” Towers was pitched through the front controls, and both aviators emerged at the surface about ten seconds later, where they “found the machine floating upside down.” Not only were the two aviators unhurt, but also the A-1 itself was found salvageable and was successfully repaired. Three panels, the front control, and one aileron had been broken and the right wing float had been crushed. It was concluded that the engine had failed when a wire leading to the magneto had broken.

While propeller tests were being conducted on 2 September, another serious mishap occurred to the A-1. Its propeller struck the water so hard during a turn in three-foot high waves that the propeller hub was fractured. Half the propeller was hurled into the lower right rail bamboo instantly snapping it. The other half thrashed the air, struck the broken bamboo, and jarred the engine bed loose. The bow of the pontoon, meantime, was fractured by slamming waves. The A-1 was towed ashore before it sank, and repairs were made the following day. By 4 September, the machine was ready to fly again.

The other airplane ordered from Curtiss, designated A-2, was assembled and prepared for testing by 13 July. It was a single-place, standard Curtiss biplane equipped with three wheels for ground take-offs and landings. It was designed to serve as a training plane for the embryonic Navy aviation unit.

The A-2 weighed 987 pounds without water, gas, oil, or pilot. The biwings measured 28 feet, 8 inches in length, and 5 feet in width; they were spaced 5 feet apart. The ailerons, extending outward and backward from a position midway between the trailing edge of the biwing tips, measured about 11 feet by 5 feet. The cost of the A-2 was $5,000.

The A-2 was powered by a straight 4-cylinder pusher-type engine that developed 50 h.p. the 4-clinders had a 4-inch bore and 4-inch stroke. The engine weighed nearly 220 pounds and turned at about 1,200 r.p.m. The propeller measured 7 feet, 4 inches in length, weighed 16 ½ pounds, and developed 350 pounds thrust. The fuel tank could hold up to 9 gallons of gasoline.

Lieutenant Ellyson test-flew the A-2 on 13 July, and four days later (in a letter to Captain Chambers) he expressed hope that the Navy Department would formally accept both the A-1 and A-2 as soon as possible. Ellyson was worried—particularly about the single-place A-2 trainer biplane. He feared that the A-2 might become smashed by Towers or himself during test flights, and he felt that the A-2 should legally be in the Navy’s possession so Curtiss would not suffer undue repair costs for their mistakes. Ellyson’s fear was well-founded.

The following day he took the A-2 land plane aloft and deliberately alighted it on the water to test its ability to float. Hydro boards had been attached to the A-2 to give it some buoyancy in the water, but these proved far from adequate. Upon hitting the water, Ellyson was thrown against the controls, breaking the push rod. The hydro boards broke, too, but, instead of somersaulting or sinking, the A-2 floated with a pronounced list. The plane was patched the same day. On 21 July, Ellyson undertook the same experiment after attaching and bracing the hydro boards more securely than before. No damage occurred this time and the A-2 remained afloat after striking the water. Ellyson, however, had to slip out the pilot's seat to keep the A-2 from careening.

Altogether, Ellyson flew the A-2 12 times during the summer of 1911, for a duration of 54 minutes. Towers, while practicing to gain sufficient flight proficiency to qualify for his pilot's license, flew 25 one-minute hops on 18 and 19 July. He struck the ground so hard on his last hop of the 19th that the A-2's front wheel was destroyed.

Near the end of summer, Towers believed his practice in the A-2 and A-1had prepared him sufficiently to try for his pilot's license. Early in September, therefore, the A-2 was fitted with a Curtiss 8-cylinder 60 h.p. engine borrowed especially for the test. And on 11 September, Towers made his first attempt. But like Ellyson, Towers failed on his first try when he made a faulty landing. Two days later, Towers successfully fulfilled the necessary requirements and earned Aero Club of America pilot's license No. 62.

Six weeks earlier, in August 1911, Lieutenant John Rodgers had qualified for his pilot's license at Dayton, Ohio. He was awarded Aero Club of America pilot's license No. 48.

From 10 September to 17 September, when the A-2 was disassembled, crated, and shipped to Annapolis, Towers made 27 flights in the A-2 (including his license qualification flights), which lasted a little more than seven hours duration. These flights averaged 15 minutes each, and were flown between 150 and 2,500 feet in altitude.

Theodore Ellyson and Glenn Curtiss collaborated in early September to erect an elaborate airplane launching device at Hammondsport to test its feasibility for possible shipboard application. They constructed a wooden platform 16 feet high and about 150 feet from the water's edge. Three-quarter-inch wire cable was then stretched taut from the platform to a stake driven below the water's surface, forming an angle of about ten degrees with the water and shoreline. Ellyson undertook to fly the A-1 off this apparatus on 7 September 1911.

Ellyson became successfully airborne after traveling 150 feet of the 250-foot cable. Curtiss hailed the experiment as the answer to the Navy's need for a shipboard appliance to launch aircraft. Captain Chambers, however, foreseeing the variable weather conditions that would come into play, felt that the device would be too unsteady for use on the deck of a rolling ship.

While the fledgling naval aviators were practicing flying and qualifying for their licenses at Hammondsport and Dayton, Captain Chambers, attended to the required administrative details at his office in Washington, D.C. In addition to directing the activities of the three naval -pilots, visiting them on occasion, contracting for and inspecting new aircraft, recruiting officer trainees, overseeing construction of a sui table naval aerodrome, as well as investigating new developments in aeronautics by digesting the literature and attending exhibits relating to aviation, his work entailed writing voluminous correspondence and conducting numerous interviews with aviation enthusiasts, inventors and would-be inventors, aircraft manufacturers, promoters, newspapermen, and occasional crackpots. Scores of letters poured into his cramped working space, offering to construct (generally for a large price) freshly conceived flying machines of many assorted sizes, shapes, and forms. Captain Chambers courteously answered each proposal no matter how small its merit or preposterous its conception. He patiently pointed out shortcomings and encouraged various correspondents to design and construct airframes and engines useful for purposes of naval aviation.

The important work of the summer was not over. Naval aviation had progressed significantly during these few months. The first three Navy fliers had completed their training. They had earned their licenses and could now train new aviation candidates to fly. The first three Navy planes had been constructed, tested, and accepted.

The two contingents at the Curtiss and the Wright training schools were now ready to be joined as a single unit at a naval aerodrome established for aeronautical operations, experimentation, and training of new naval aviators. At first it was undecided whether to establish the Navy aerodrome on government property just outside Washington, D.C., or at Annapolis, Maryland, where many cadets had filed applications for aviation training and where the facilities of the Engineering Experiment Station were close at hand. Annapolis was finally selected and an aerodrome was prepared, where the separate naval flying units were joined in the autumn of 1911.

Airborne on fragile, new wings, the fledglings moved out cautiously into the "real" world of the Navy—naval aviation was growing.