The biggest obstacle to creating breech-loading cannon was to ensure that, when the firing lanyard was pulled, the resulting explosive force exited the barrel at the muzzle and not back at the gun crew. Although several inventive ideas were tried, it was not until the 1860s that Alfred Krupp developed perhaps the most successful design to achieve this, depending on both good design and improvements in metallurgy. Krupp synthesized ideas from other attempts to create a gun whose basic elements would go on to be found in everything from the Prussian artillery that helped defeat France in 1871 to the 38.5-centimeter (cm) guns of the mighty Bismarck that sank HMS Hood in 1941. A sliding-wedge breechblock can still be found in almost all systems whose ordnance uses cased and fixed ammunition.

The Broadwell Ring

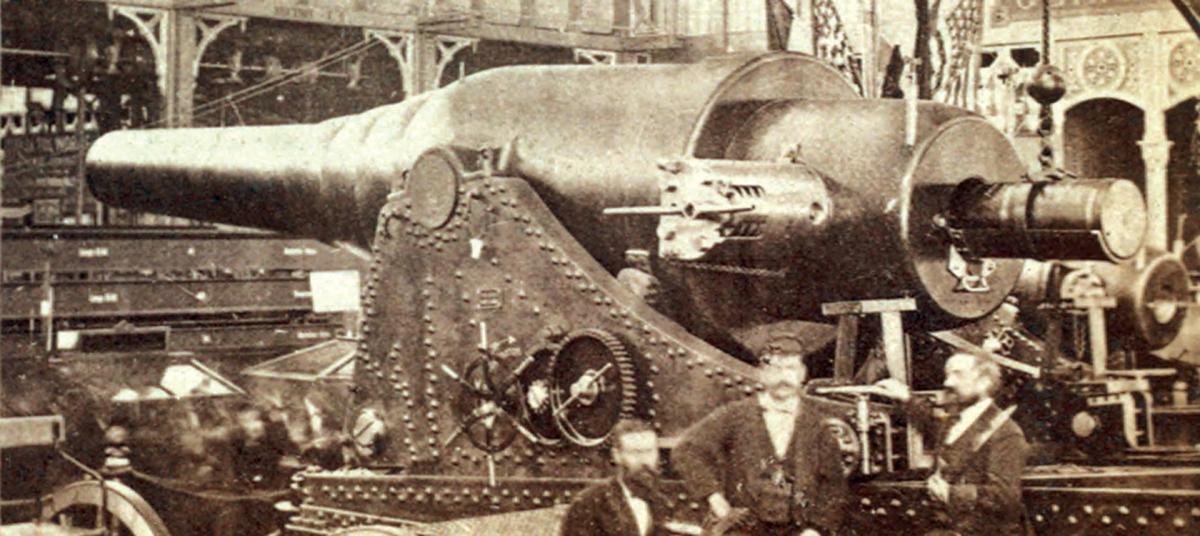

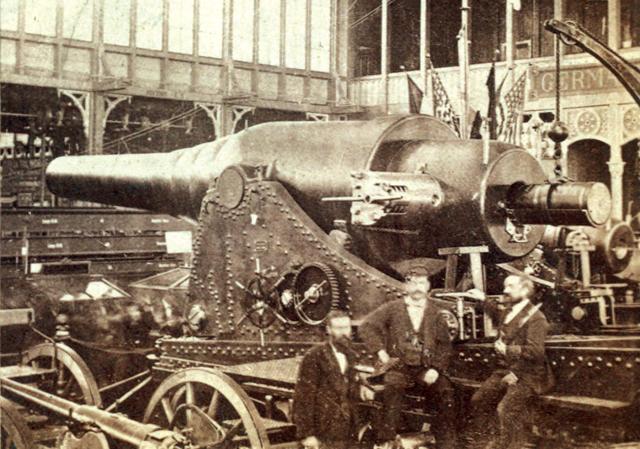

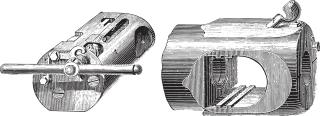

In 1866, Lewis W. Broadwell patented a design for a cannon using a horizontal sliding breechblock that included an effective sealing-ring design that was soon widely adopted. Broadwell’s design used a rectangular breechblock that slid horizontally in a carefully cut slot or mortise set at a right angle to the axis of the gun and located about one and a half calibers from the rear. The breechblock was pushed home by hand, but it was provided with a locking screw both to ensure that the breech was tightly and precisely closed and to facilitate opening after firing. His main innovation was the provision of a circular steel faceplate on the block, of a circumference greater than the chamber bore, which, when the block was closed and locked, compressed a conical ring that rested in an annular groove in the breech to form a gas-tight seal, which became known as the “Broadwell ring.”

Krupp adopted and then improved on Broadwell’s design in several ways. First, Krupp used high-quality steel (which his firm produced) for superior strength, instead of cast iron or bronze. Second, he gave the rear of the block a semicircular shape that improved stress distribution. In addition to the locking screw, he also provided a traveling screw that engaged the top of the block and the roof of the mortise opening for the entire length of the block. This greatly improved the speed and precision of opening and closing the breech.

Rifling and Hooping

Krupp’s early work produced relatively light guns, field artillery made exclusively for the Prussian Army. But Prussia also needed guns that could throw a heavier projectile for coastal defenses and, after 1871, to equip the ships of the newly created Kaiserliche Marine. To create these, Krupp borrowed ideas from British Army Captain T. Alexander Blakely, who is credited with developing the first built-up rifled artillery. (“Rifled” barrels give departing rounds an axial spin that improves range and accuracy.)

Black powder, the propellant used until smokeless powder’s invention in 1884, burns rapidly and creates enormous pressures in the chamber, necessitating additional strengthening for large guns. The designers of the muzzle-loading shell guns of the era solved this problem by increasing the thickness of the cast iron around the chamber, creating a distinctive soda-bottle shape, the most famous example being the Dahlgren guns used in the Civil War. But this shape does not work for breech loaders.

Blakely patented the idea of shrinking wrought-iron or steel hoops around a rifled tube to reinforce the chamber. The shrinking process created tension in the metal, strengthening the chamber and enabling it to withstand greater pressure than could an equivalent thickness of homogenous material. This resulted in lightweight built-up guns that could use bigger charges than heavier solid-cast guns. Krupp’s further innovation was to layer thin steel hoops, keyed one into the other, to create even stronger built-up breech-loading guns, whose ratio of gun weight to charge was even better.

Krupp produced naval guns in the late 19th century in sizes ranging from 5 cm to 30.5 cm, about 2 to 12 inches. The smaller guns used fixed, brass-cased ammunition, while the larger guns used bagged charges and separate shaped projectiles with copper bands at their base that engaged the rifling in the barrel. Heavy coastal and naval guns of this era were mounted on a sliding, angled carriage with a sophisticated glycerin-filled hydraulic cylinder to absorb recoil. The projectile was placed on a loading tray, and both were hoisted to the breech opening, where the loading tray was hooked to the rear of the gun. The projectile was rammed home, followed by the powder bag. The sliding breech was closed, and a friction primer was thrust through a hole in the sliding block to pierce the powder bag. The gun was ready for firing. For traverse, the carriage sat on either casters or a steam-powered rotating gun turntable set within an armored barbette.

On the Firing Line

The first real test of Krupp’s big naval guns came at the September 1894 Battle of the Yalu River, during which the Chinese ironclad Zhenyuan scored a devastating hit with one of her 30.5-cm guns on the Japanese flagship Matsushima. The overall effectiveness of the big guns, however, was much diminished by their slow rate of fire, estimated in a British Admiralty analysis of the battle to be three to five minutes per round. By comparison, smaller guns that used fixed ammunition could fire many rounds per minute. In both cases, the loading process was entirely manual. The sliding breech could be closed very rapidly, but the weight of the shells (330 kilograms for the 30.5-cm round) made loading slow and laborious.

Tangent ladder sights mounted on either side of the breech were used to aim, one for elevation and the other for training. When the gun captain was ready, he pulled the lanyard to fire the gun. The lack of telescopic sights and the jerky operation of the steam-powered gun platform meant the gunners would be lucky to hit a moving target beyond 1,000 yards.

Within just a few years, though, the introduction of hydraulic or electric-powered ammunition hoists, rammers, elevating screws, and training gear greatly improved the firing rate of heavy guns. These improvements, coupled with the new smokeless powder and the introduction of longer gun barrels, led to the big gun becoming the naval weapon of choice. The use of telescopic gun sights and stereoscopic rangefinders greatly increased accuracy and effective range, such that during the Russo-Japanese War (1904–5), heavy guns could engage targets at 6,000 yards and beyond, firing several rounds per minute, with devastating results.

As long-range, high-rate-of-fire gunnery matured, Krupp’s next major innovation was the introduction of the Schnelladekannon—known as the SK—“fast loading” series of large-caliber guns that used brass-alloy metallic powder cartridges. The cartridge case contained the main propellant charge and was built with a rim that provided improved obturation (sealing) and incorporated the primer in the base, effectively bringing to the heavy guns the simpler, faster loading system that was found on the smaller-caliber quick-firing secondary guns. (The largest guns also used an additional fore charge.) The horizontal sliding breech was now power operated. And, after firing, the spent cartridge was ejected automatically when the breech was opened. Empty cases then were capped to trap any remaining gases and manually ejected through a port in the rear of the gun house.

German battleships typically mounted guns in pairs, and the horizontal breech design allowed the gun to be built with the breech opening to either the left or the right, depending on which side the gun was mounted. Ventilation ducts between the guns extracted smoke and fumes from the chamber of either gun as the breechblock slid open. Combined with the use of metal casings, this greatly lessened any danger from the blowback of flaming residue, which could accidentally ignite a silk powder bag, a frequent accident before the introduction of gas-ejection systems.

Once More unto the Breech

Krupp’s sliding breechblock design contributed to the German SK guns’ greater rate of fire than those of other militaries. The sliding breechblock did not interfere with the loading process, and primers built into shell casings shaved vital seconds off load times. The use of brass cartridges also simplified handling and saved time in the magazine.

In 1921, the British raised the German battleship Baden from the mud at Scapa Flow and conducted firing trials. They compared the rate of fire of her 38-cm Krupp guns with the 15-inch guns of HMS Queen Elizabeth. The British found that the loading and firing cycle of the German gun was 13 seconds less, thanks in no small part to the rapidity of opening and closing the horizontal breech block. Altogether, Krupp’s design facilitated a firing rate that was faster than that of the enemy, which allowed German gunners more opportunity for hitting in salvo firing.

German brass cartridges also reduced the danger from the ignition of propellants, as was demonstrated on two occasions when the battle cruiser Seydlitz suffered hits on her after turrets that left them utterly burnt out, but the ship did not experience a catastrophic magazine explosion. It is a bitter irony that, to match German rates of fire, Vice Admiral Sir David Beatty’s battle cruisers resorted to extremely unsafe cordite stowage and handling practices within gun turrets that ultimately led to the destruction of three of them at the Battle of Jutland.

The Krupp sliding horizontal breechblock briefly entered service in the U.S. Navy when the former Kriegsmarine heavy cruiser Prinz Eugen became the USS Prinz Eugen (IX-300) in 1946. The Bureau of Ships put her through her paces with test firing and maneuvers with a crew of 8 officers and 85 enlisted men of the U.S. Navy supervising 27 German officers and 547 enlisted sailors. She ended her service as a target ship during Operation Crossroads, the atomic tests at the Bikini Atoll, in July 1946.

Sources:

1. Lewis Wells Broadwell, U.S. Patent No.55,762, “Improvement in Breech-Loading Ordnance,” awarded 19 June 1866.

2. LT Edward W. Very, USN, Navies of the World, (New York: John Wiley & Sons, 1880).

3. ADM 231-25, Anon., “Narrative of Naval Engagement off the Yalu River, with Remarks Thereon” (M931/95), Admiralty Intelligence Department, March 1895.

4. J. F. V. Kronenfels, ed., Die Kriegsschiffbauten, 1881–1882 (Leipzig, Germany: A. Hartleben’s Verlag, 1883); Maritime Reprints Band II (Munich, Germany: Christian Schmidt’s Verlag, 1976); author’s collection.

5. Vz-Adm. Karl Galster, Die Schiffs- and Kustengeschutze der deutschen Marine (Berlin, Germany: Siegfried Mittler, 1885).

6. ADM 186-251, Anon., “Progress in Gunnery Material, 1921.”

7. Nicholas A. Lambert, “‘Our Bloody Ships or Our Bloody System’? Jutland and the Loss of the Battle Cruisers,” The Journal of Military History 62, no. 1 (January 1998): 29–55.

8. Norman Friedman, Naval Weapons of World War One (Barnsley, UK: Seaforth Publishing, 2011).

9. U.S. Navy, “Testing the Eugen,” All Hands, NAVPERS-O no. 348, March 1946, 45.