The new Zumwalt (DDG-1000)-class destroyers present the ship-handler with challenges and advantages very different from traditional combatants. Once these differences are understood and mastered, the Zumwalts perform well, especially for ships of their size, and are a joy to drive. As a weapons officer and plank owner assigned to the Zumwalt, I hope this article will serve as a reference for future sailors in the class. It is based on sea trials in Bath, Maine, and our first months of operations. With the Michael Monsoor (DDG-1001) and Lyndon B. Johnson (DDG-1002) joining the fleet soon, the shiphandling debates and collegial competition that typically energize wardrooms will, I hope, benefit from this experience.

The Ship

The Ship

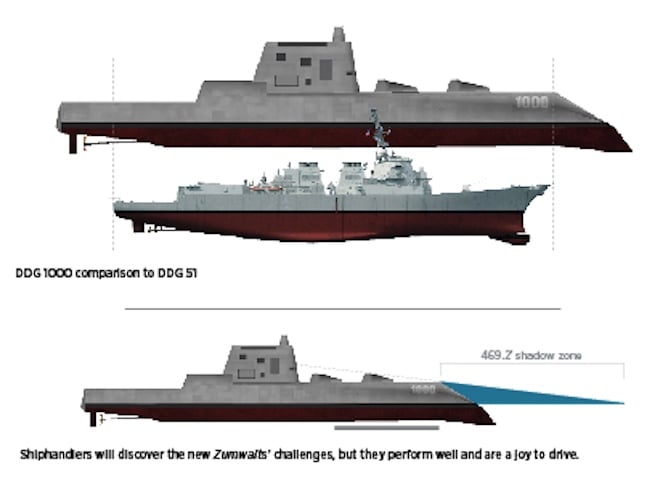

To understand the Zumwalt’s handling characteristics, it is necessary to highlight some of the key similarities with and differences from other surface combatants. The ship uses a “tumblehome” design, meaning the hull narrows with greater distance above the waterline. Unique to the modern U.S. Navy, this design was used on wooden warships for centuries and was prevalent until the late 1800s. The defining tumblehome feature is the way in which the bow cuts through the waves rather than riding over them, which has both pros and cons.

On the plus side, the ship’s performance is not degraded in sea states up through 6 (significant wave height of 13–20 feet). For example, the Zumwalt attained a top speed of 30+ knots in 12-foot seas. Additionally, the hull form provides a much lower radar cross-section. For a “stealth destroyer,” this is imperative.

There is also a common misconception that Zumwalt-class ships are one big wave away from submerging or capsizing. However, the Navy tested a model of the tumblehome more than any other hull design the service has ever built. This background, along with our at-sea operations, provides evidence that the ship can withstand seas worse than anything an Arleigh Burke (DDG-51)–class destroyer or a Ticonderoga (CG-47)-class cruiser can tolerate.

That said, extremely large seas taken on the bow could submerge the forecastle, resulting in damage to equipment or the bow. Also, the ship’s righting arm is several times larger than an Arleigh Burke’s. Generally this results in exceptional stability with minimal (<5 degrees) pitch and roll. However, if the ship were taking extremely large seas on the stern quarter or beam, with rolls greater than 15 degrees, the large righting arm would force the ship back to centerline much faster than on other ships—causing significant G-forces that could damage equipment or injure personnel.

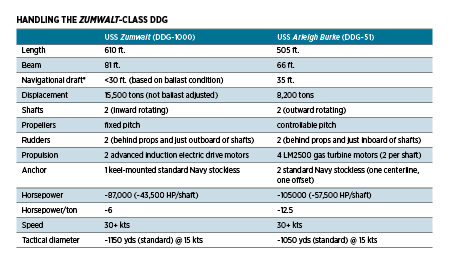

The Zumwalt is also the only surface-combatant class in the Navy that uses electric-drive propulsion. Power is provided by four gas turbine engine–electrical generators with a combined output of ~78 megawatts, nearly ten times that of an Arleigh Burke. To put this in perspective, the ship generates approximately four cruisers’ worth of excess power while operating at 20 knots.

This power is available for every load—combat systems, lighting, engineering equipment, propulsion, etc. Unlike an Arleigh Burke, the ship does not use gas turbine engines for propulsion. Rather, power drawn from the gas turbine generators drives two advanced induction motors (AIMs), one per shaft, similar to those used in the Royal Navy’s Type 45 destroyer design. Nor do the Zumwalts use main reduction gears. Instead, the AIMs are directly coupled to the shafts.

With significantly more tonnage and less horsepower than an Arleigh Burke, the Zumwalt should, as Captain R. S. Crenshaw points out in Naval Shiphandling, accelerate much more slowly.1 However, the AIMs produce enormous instantaneous torque, which neutralizes the Arleigh Burke’s horsepower advantage and enables the Zumwalt to accelerate almost as quickly.

Electric drive propulsion is also more fuel-efficient. The AIMs draw power from generators that operate at constant revolutions per minute (RPM). By contrast, gas turbine engines on an Arleigh Burke vary RPM depending on the ordered speed. The same concept applies to driving a car: maintaining a constant speed of 60 miles per hour uses less gas than frequently accelerating and decelerating.

Finally, the ship has two shafts and fixed pitch propellers, which turn inboard for an ahead bell and outboard when propelling astern. Shaft RPM ranges from a minimum of 25 to a maximum of approximately 150 ahead and 100 astern; as a rule of thumb, 5 RPM equates to 1 knot, which enables the ship to reach a top speed in excess of 30 knots. Two rudders, proportionally larger than those on an Arleigh Burke or Ticonderoga, are located behind the screws, just outboard of the shafts. These are operated by an all-electric actuating system that provides roughly twice the speed of rudder swing as a traditional electro-hydraulic system. The combination of the large rudders and accelerated rudder swing creates very good turning performance.

The ship has a conventional ballast system (her fuel tanks are not compensated). At a normal ballast condition, she displaces ~15,500 tons and has a draft of less than 30 ft. The advantage of this system is flexibility. Different ballast conditions are better for stability than performance, and vice versa. When used properly, variable draft is a powerful tool. Nevertheless, ballasting up or down can take hours. Poor planning could lead to an improper ballast condition that degrades performance or stability.

Performance at Sea

As noted, much has been made of the ship’s tumblehome hull design and its perceived lack of stability.2 In early operations the ship displayed good sea keeping, even at high speeds, and very good vertical and axial stability. Shiphandlers must keep in mind six attributes:

1. The tumblehome bow design cuts through seas but also produces an extended surge distance. The combination of the tumblehome and the fixed pitch propellers, which must change direction of rotation to generate astern propulsion, creates a stopping distance greater than those of an Arleigh Burke or a Ticonderoga.

2. The ship’s broad, shallow stern, in conjunction with the tumblehome hull design and substantial metacentric height, enables her to steady up during a turn much faster than an Arleigh Burke. Regardless of the speed and rudder combination, all that is needed is a “rudder amidships” order 5 to 10 degrees in advance of the desired heading. The DDG-1000’s shallow stern also slides during a turn rather than digging, which produces a flat turn (around 7 degrees heel at maximum speed with maximum rudder in light seas) and drastically reduces the squatting effect in shallows.

3. The large sail area produced by the broad flat surfaces of the hull and deck house has the same effect as on other ships, making it easier to turn into the wind than out of it (the weathervane effect), and more difficult to hold a course if the wind is abaft the beam at slow speeds. The large sail area also makes the ship difficult to moor in offsetting winds.

4. The variable draft, if properly utilized, can improve performance in different sea states and reduce the effect of environmental conditions including wind and current.

5. A keel anchor is fitted at frame 30 (frames on DDG-1000s are notated in meters), forward of the forward-most gun mount, and is operated from below deck. This sole anchor has an extended shank that aligns it in the hull but also requires a minimum of 12 feet of water below the keel for operation—making it difficult to anchor in shallow water or place the anchor underfoot when pierside. Because the anchor is well behind and below the sonar dome, however, it is not necessary to gain sternway before letting go, which is particularly useful when forced to enter an anchorage with winds abaft the beam.

6. The radar cross-section is significantly less than that of an Arleigh Burke. Merchant ships, which frequently use a small bridge watch team and rely on radar alarms to alert them to approaching vessels, are especially susceptible to dismissing the Zumwalt’s radar return. This means bridge watchstanders must be trained differently. They still adhere to the various rules of the road governing ship interactions, but they must assume that other vessels may not give way or act in accordance with their expectations.

Performance in Restricted Waters

Crenshaw points out in Naval Shiphandling that for a large ship, “the time lag between order and result is greater and the margin for error is less.”3 The combination of the Zumwalt’s size and inability to switch quickly from ahead to astern propulsion or vice versa (because of fixed pitch propellers) creates substantially more inertia than on a smaller vessel, a characteristic magnified by the large sail area. Shiphandlers should heed Crenshaw’s advice and plan moves well in advance. Nowhere is this more apparent than during mooring evolutions, when design characteristics unique to the class must be taken into account:

• The outward-sloping tumblehome design creates the illusion that the ship is farther away from the pier than it is. The shiphandler must recalibrate the “seaman’s eye” to account for this.

• All the mooring stations are internal. While the benefits of this include protection from the elements, it also makes it impossible for the bridge to see progress in the mooring stations. Good interstation communications are imperative.

• The tumblehome and internal mooring stations drive tug placement, which is farther aft for the forward tug than most pilots prefer. Using tugs is preferable for mooring or getting under way, but they are not required. The ship does have enough power, bolstered by instantaneous torque, to execute a reverse twist. In contrast to a normal twist, where the rudder angle and engine configuration cause the ship to twist in the same direction (right rudder, port engine ahead; starboard engine back), a reverse twist involves opposing the engine and rudder (left rudder, port engine ahead; starboard engine back). This causes the entire ship to “walk” sideways with minimal twist.

• A relatively low height of eye of 35 feet, along with large gun mounts on the forecastle, result in a substantial shadow zone of 469.2 feet dead ahead.

• The ship has no bridge wings, but has “alcoves” with two manually operated, inward-opening windows per side. Each alcove is the size of a small bridge wing, with plenty of room for a commanding officer, conning officer, and pilot. Because the ship’s sides are flush, with minimal obstruction, shiphandlers can lean out the side windows to ascertain easily the relative motion of the bow or stern. Visibility of the stern quarter is relatively good, although one cannot quite see the aft corner of the flight deck.

This new class has unique advantages and challenges. At sea, the tumblehome hull design, electric-drive propulsion, and broad, flat stern create a powerful, responsive, and agile platform. Entering port, the ship is capable, but shiphandlers must respect her size and factor in the time lag between order and response her momentum requires. Once these challenges and advantages are understood, a good shiphandler will quickly adapt and find that the DDG-1000s are worthy keepers of the “Greyhounds of the Sea” legacy. Sleek and graceful in lines (they grow on you), they are quick in acceleration and top speed, as well as nimble in their maneuver.

1. CAPT R. S. Crenshaw, USN, Naval Shiphandling, 4th ed. (Annapolis MD: Naval Institute Press, 1977), 212.

2. Robert Charles, “The Navy’s Zumwalt Problem,” Washington Times, 28 November 2016; Jordan Crucchiola, “The New $3B USS Zumwalt Is a Stealthy Oddity That May Already Be a Relic,” Wired, 10 December 2015.

3. Crenshaw, Naval Shiphandling, 215.

Lieutenant Lillie graduated from the University of Notre Dame. After qualifying on board the USS Laboon (DDG-58), he was assigned to the USS Zumwalt (DDG-1000), where he was a plank owner serving as the weapons officer.