To Build Trident

By Gerard Keith Burke

In the 1980s, the land-based missile portion of the nation's strategic triad will become theoretically vulnerable to a preemptive Soviet strike. The manned bombers are growing older, and doubts are being continually raised about their ability to penetrate the sophisticated air defenses of the 1980s which will be equipped with look-down, shoot-down capabilities. Additional questions are being raised about the B-52s' ability to survive an attack on their bases.

At sea, the nation's ballistic missile-armed submarines (SSBNs) are verging upon obsolescence. Commissioned from 1959 to 1967, the 41 ships of the George Washington (SSBN-598), Ethan Allen (SSBN-608), and Lafayette/Benjamin Franklin (SSBN-616/640) classes are reaching the point where they must be replaced. Built to serve 20 years, it is becoming increasingly costly to maintain and overhaul them. There are doubts concerning the reliability of key components, such as the propulsion plant, and it is probable that after a five-year extension increases the life-cycle of the 31 Lafayettes/Benjamin Franklins to 25 years they will have to be replaced.1

The ultimate replacement for the existing fleet lies in the modern Ohio (SSBN-726) class, even though the 12 Benjamin Franklins will be rearmed once again, this time with the Trident I missile. At this writing, the Five-Year Shipbuilding Plan calls for 13 Ohio-class submarines to be delivered, and for each one to be armed with 24 Trident I missiles.2

These ships will be the most formidable ballistic missile submarines ever constructed in the West. They will have a submerged displacement of 18,750 tons and a length of 559 feet. Should U. S. national priorities require it, up to two of these awesome underseas dreadnoughts can be delivered per year.

As for the missile, the Trident I (C-4) has the same length (34 feet), diameter (74 inches), and weight (65 ,000 pounds) as the Poseidon (C-3). On the other hand, it has far more range (4,000 nm. contrasted to 2,500 nm.), more accuracy (.25 nm. contrasted to .3 nm.), and a more powerful warhead package (100 KT x 7 contrasted to 40 KT x 10).3

Perhaps most important, this new missile is able to undergo significant upgrading. As it is, it can fit into the Ohio-classSSBNs and be retro-fitted into the older 616/640 series. With a longer first-stage motor, one that will fill the tube in the Ohio-classSSBNs, more range may be added, or more accuracy at the former range with the old payload. Alternatively, diameter and length can be increased for still greater range and payload, or the payload could be increased still further, but at the cost of some range.4

Ultimately, it is to be hoped that the Trident I will yield to the Trident II (D-5). This weapon promises to be an improvement by whole orders of magnitude upon either the Poseidon (C-3) or the Trident I (C-4). Presently, its configuration is not certain. Nevertheless, it should possess a diameter of 83 inches, a warhead package of 335 KT x 10, and an accuracy of around 700 feet.5

However, this feature will not deal primarily with the strategic implications of the sea-based deterrent of the future, but rather the problems the program encountered and the techniques used to overcome them.

With the ship configuration chosen, the challenge became one of construction. And since the Electric Boat Division of General Dynamics Corporation was the firm chosen as the principal contractor for the submarine, it is necessary to examine its approach to the task.

First, submarine size has been moving upward throughout this century. For example, since 1899 when Electric Boat was founded to complete the work on America's first effective submarine, the 54-foot Holland (SS-1), the size has increased to the great dimensions of the ballistic missile submarines of today—380 feet in the time of the George Washington, 410 feet during the Ethan Allen construction, 425 feet in the case of the Lafayette/Benjamin Franklin classes, and 559 feet for the Ohio. This evolution, especially the quantum jump required for the Ohio program, had reached a point where it was taxing the capacity of the yard.

Second, construction must also be seen in terms of the physical size of the facility . Electric Boat has been located at Groton, Connecticut, since 1911. Even though it had no shipyard of its own until 1924 (it simply designed submarines prior to this date) or constructed a submarine for the U. S. Navy until 1931, its yard was becoming cramped for space in the 1970s.

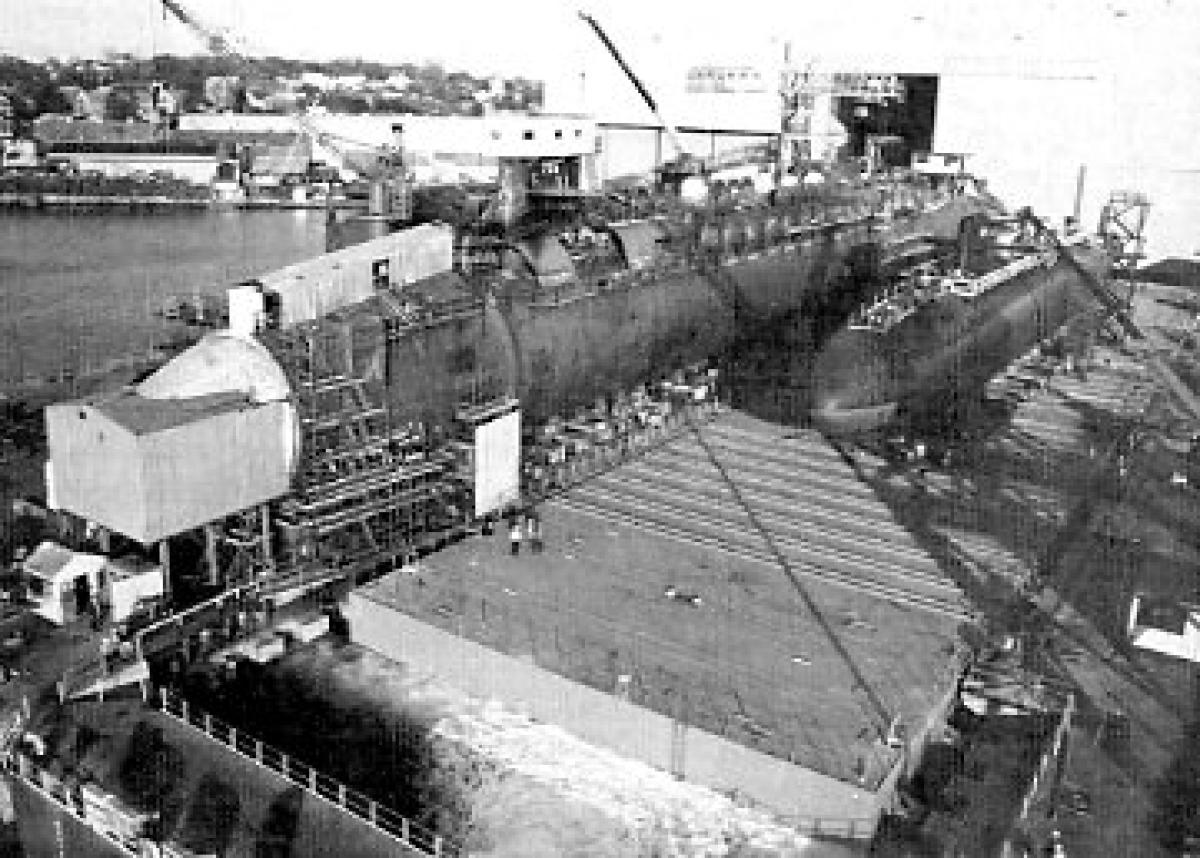

To solve these problems it was decided to rebuild one whole section of the Groton yard and to move a portion of the operation to the old Naval Air Station at Quonset Point, Rhode Island. The first portion of this operation involved the establishment of what is known as a Land Level Submarine Construction Facility at Groton. Construction of this facility enables an entire submarine to be assembled at Groton, where essential technologicalresources are located.

The salient features of the Land Level Facility are: (1) Building 260—a vast enclosed construction area consisting of four bays—(486 feet long x 260 feet wide x 137 feet high); (2) the North Pier (653 feet long x 170 feet wide), the South Pier (598 feet long x 99 feet wide), and a graving dock (617 feet long x 96 feet 6 inches wide); (3) a series of eight cranes—a 300-ton portal crane, two 280-ton bridge cranes, four 25-ton bridge cranes, and a 100-ton hammerhead crane. These improvements cost $140 million and took from 1973 to 1976 to complete.

The second phase of the operation called for the transfer of the plate yard, rolls, and presses to the newly leased Quonset Point facility. Acquired in 1974, this facility today fabricates hull cylinders, subassemblies, and other components. The construction of an Ohio-classSSBN begins here.

An Ohio class-SSBN is constructed in cylindrical-shaped sections. As noted, these are fabricated at Quonset Point and then barged 50 miles to Groton. The advantages in using this method are apparent when modern techniques are compared with those of the past.

In an earlier epoch, the hull sections (each around 13 feet long) were welded together to form the entire pressure hull enclosure. At that point three holes were cut in the top to facilitate loading machinery, and men began working inside the hull, under frequently cramped conditions. The men worked from the outside in, and if a mistake was discovered near the center of the hull, then frequently all the intervening work would have to be removed. This was both time consuming and costly.

Today, when the hull section arrives, the 300-ton portal crane lifts it into bay number 2. This bay, along with bays 3, 4, and 5, is enclosed, thus easing the problems caused by climatic fluctuations.

In this bay the hull cylinders are combined into basic sections, and the heavy machinery is installed. To aid this process, two 280-ton bridge cranes have been incorporated into the facility. These have the capacity to "fly" a 300-ton cylinder with a diameter of 50 feet over another cylinder of the same dimension. Should production jams occur, this "flying" capability can create a bypass, and enable work to continue. As important, the men working on these cylindrical sections are not in the cramped space of the hull, but rather in a much more efficient "shop atmosphere" with far more room to maneuver.

At the end of this stage, the sections are erected on supports known as strongbacks. The strongbacks are, in turn, mounted on transfer cars which are self-propelled hydraulic jacks. These jacks move on a grid of rails running throughout the entire Land Level Facility, enabling the sections to move from bay to bay.

From this point the cylinders move to another bay and are joined into larger sections. Major mechanical and structural components are added at this time. Included would be the bulkheads, tanks, piping, wiring, and cabling. As the sections are completed, they are moved to the outboard erection platform where they are joined to form a complete hull. When a ship is ready for launching, she is moved onto the pontoon. In the case of the Ohio, 31 strongbacks and 93 transfer cars were necessary to effect this move.

With the ship prepared, the 37 million gallon graving dock is flooded, and the ship moves laterally onto the pontoon. The transfer cars are removed, and the dock is pumped out leaving the ship and her strongbacks on the pontoon. Final checkouts are completed at this point, and the basin is once again flooded. This time the pontoon is flooded also. It and the strongbacks remain on the bottom. The ship floats free and is ready for christening. The unusual aspect of this type of launch is that the ship is al ready in the water at the time of the ceremony.

If the SSBN is to continue as a cost-effective program, however, its construction techniques must move forward in this changing world of technology. In this sense, the future would appear hopeful. The modern SSBN construction facilities at Electric Boat are able to be expanded so that off-site assembly and partial assembly of hull structures would be possible. These would then be introduced into the Land Level Facility for the balance of the construction cycle. This process would shorten the necessary construction time and significantly increase total output potential. In addition, the Groton site can be expanded to the south in a manner that would nearly double the output.

Of more immediate interest for the future of the SSBN program, however, is the work currently going on at Quonset Point. Here, $110 million is being spent to build the world's first Automated Submarine Frame and Cylinder Manufacturing Facility. The work commenced in November 1978, and is to be completed in 1979. The advantages these innovations will produce are simple. Since 1933 submarine hulls have been welded. But much of this work has used antiquated methods encompassing many highly manpower-intensive stages for weld preparation and fit up. For example, since no two cylinders were ever cut precisely the same, in order to make them fit, repeated operations were necessary.

Today, technology pioneered during the construction of liquefied natural gas ships has solved this problem. It is now possible with automated machinery to precisely roll and cut the cylinders so that they will fit together with consistency. In addition, automated, machine-controlled welding will reduce some operations by a factor of four. The savings to be realized from this automation are not precise, but they could run to 50% of the labor cost for cylinder construction alone.

When fully operational, the Automated Facility will have sufficient capacity to provide Groton with hull cylinders and to service other construction facilities as well. For example, it would be possible for the Quonset Point facility to provide the Newport News Shipbuilding yard in Virginia with hull cylinders for those Los Angeles (SSN-688)-class attack submarines being constructed there. Currently, this yard purchases hull cylinders from Vickers in Canada.

Although it may be stating the obvious, much about Trident is revolutionary. The Ohio class is not merely an improved Benjamin Franklin; it is new technology. Under these conditions, difficulties were bound to be experienced with the lead ship.

One area of contention is the schedule. The schedule laid down by Electric Boat on 15 October 197 1 called for the launch of the 726 to be in the first quarter of 1980, and delivery to be in the first quarter of 1981. Had dates remained unchanged, today the program would be ahead of schedule since the 726 was launched in April 1979, and tentatively the ship is to be delivered in November of 1980. However, when the construction contract was signed on 25 July 1974, a contract delivery date of April 1979 was agreed to, with a best-effort delivery date of December 1977. Thus, today the Ohio is 19 months off schedule.

This is a good example of a situation in which the prime contractor had but one customer, and the customer was too impatient. But this is not the whole story; other forces were at play:

- The office of the Chief of Naval Operations did not deliver approval of the ship's characteristics until ten months after it was due.

- The Long Lead Materials Contract, which included the hull steel, was awarded 18 months late.

- The Marine Draftsmen's Association was on strike for three months.

- The Navy decided on a land-based prototype for the propulsion plant. This constituted an addition to the program, and it had to be built prior to the construction of the ship's plant.

- The missile, fire control, and navigation equipment was 33 months late.

Compounding all of this were employment problems. As the schedule began to slip, tempers began to fray. Once again the "prime contractor/single impatient customer" syndrome reared its head. The offshoot was that additional workers were hired, and the Groton yard expanded from 5,000 in July 1975 to 11,000 in July 1977. At Quonset Point, the corresponding figures were 363 in July 1974 and 3,600 in July 1977. The difficulty lay in the fact that men and women with shipbuilding skills are not commonplace. The result was that the supervisory capacity of the yard was overloaded, and when the most experienced workers were made supervisors to cover the shortfall, they lacked training. Their absence from the workforce aggravated the situation.

To resolve this impasse in the SSBN program new management was recruited, arriving in the fall of 1977 under the leadership of Me. P. Takis Veliotis. Solutions were difficult but imperative. It was found necessary to immediately discharge 3,500 employees and retrain the newly appointed supervisors. The alternative was to close the yard and put 20,000 more out of work.

Today, with the ratio of skilled to unskilled workers adjusted, with the learning process over, with the work force stable, and with the workers doing the same job daily, productivity seems certain to improve. It is entirely possible that the November 1980 delivery date for the 726 may be slightly bettered.

Cost overruns also enter the picture. Primarily, it is difficult for anyone, in industry or government, to determine the cost of such a program years before the first ship enters the fleet. As a result, more than one level of pricing is used. In the case of Trident, the first four SSBNs had a contractor's target price of $984.8 million and a ceiling price of $1,283 million. (Note: the shipbuilder's cost is only around 40% of the total cost.)

The contractor will try to hit the target price, but because he is not certain he can meet this, a ceiling price is quoted. If the target price is not met, then government and the contractor must share in the additional costs. If the ceiling price is exceeded, then the contractor must pay all costs above this ceiling. At this writing, neither price has been exceeded, but the target price will eventually be passed. The ceiling price should not be exceeded, however, and it appears that the first four Tridents will reap a modest profit.

It should be noted that inflation has struck the shipbuilding industry much as it has struck the nation and the world. According to the Bureau of Labor Statistics Material Price Index, the price of maritime materials rose 34% from September 1973 to September 1974. This factor should not be included in discussions concerning cost growth overruns.6

Trident, itself, has experienced difficulties. But careful analysis indicates that collectively these problems have been the result of new technology and new processes combined with the pressure certain to be generated by a prime contractor/one customer relationship. In the end, productivity is on the upswing, labor problems are being solved, and the future of the program lends itself to optimism.

1Senate Hearings Before the Committee on Armed Services, Part 5: General Procurement, 95th Congress, 2nd session, 1978, p. 4203.

2Senate Hearings Before the Committee on Armed Services, Part 2: Authorizations, 95th Congress, 2nd session, 1978, p. 1029.

3FBM Facts: Poseidon/Trident, Washington: Strategic Systems Projects Office, 1978, pp. 6-9.

4Senate Hearings Before the Committee on ArmedServices, Part 9: Research and Development, 95th Congress, 2nd session, 1978, pp. 6681-6686.

5Edgar Vlsamer, "Toward a New World Strategy," Air Force Magazine, January 1979, pp. 60-65; Colin S. Gray, "The Future of Land-Based Missile Forces," Adelphi Papers, Number One Hundred and Forty, Winter 1977, p. 32.

6Authorizations, p. 1579.

Dr. Burke, who has been an instructor of history at the College of White Plains in New York, is currently engaged in research on defense-related topics and has written a number of articles for periodicals such as The Military Review, Comparative Strategy, and The Royal Air Force Quarterly. His article, "The Need For Trident," appeared in the November 1978 Proceedings.

Future Navy C2: A Testbed Glimpse

By Lieutenant Commander Andrew J. Dietzler, U. S. Navy, and Colonel Kenneth L. Moll, U. S. Air Force (Retired)

A Pentagon operator typed in a query on his computer terminal in plain English, asking which U. S. Navy ships were within 200 miles of Naples. In seconds, he received the answer, "Fox and Philadelphia." He then typed: "Show them to me." According to a 27 March 1978 Wall Street Journal feature article, "Computers That Use Plain English Permit Vast New Applications," the computer's display quickly presented "a map of the Mediterranean, with glowing dots representing the location of the ships."

This military application was the article's most vivid of several imaginative examples of new computer applications for government, business, scientific, and personal needs. The plain English query system is intended for military use in operational command and control or C2. The system currently is being evaluated and refined in the Advanced Command and Control Architectural Testbed (ACCAT) at San Diego.

Coordinated at Naval Ocean Systems Center, ACCAT is a joint project between the Navy and Defense Advanced Research Projects Agency. Its purpose is to transfer advanced information processing technology to Navy C2 uses. In ACCAT, new developments are repeatedly tested under varying simulated C2 environments. The experience thus gained will lead to better understood and more useful new systems.

For years advanced technology has been applied in developing new weapons, ships, and aircraft. Curiously, this has not been true in applying information processing to C2. It is not uncommon to find laboratory computer technology that is two or three generations ahead of anything that has been fielded in operational systems. Sometimes, when new C2 systems are fielded, it becomes apparent that neither the requirement nor the design has been fully thought through. In 1976, ACCAT was created to address these and similar issues.

Indeed, ACCAT offers al useful glimpse of future C2. A remote site is being planned at Pacific Fleet Headquarters in Hawaii. There, the fleet staff will operate the tactical simulation capabilities of the testbed to assess the practicality of new technology as well as operational plans. ACCAT remote sites are being installed at the Naval Postgraduate School, Monterey, California, for research and to acquire environmental data from the Fleet Numerical Weather Central. The Defense Communications Agency and other government organizations, such as the Federal Aeronautics Administration, are planning or considering their own testbeds for similar purposes.

The heart of ACCAT consists of two simulated Navy command centers that can reflect various futuristic Blue (friendly) vs. Orange (hostile) configurations for C2 at the fleet or task force level. Simply looking at the testbed doesn't reveal anything much different from what might be expected in a modern command center ashore or aboard ship.

What is unusual are the techniques and the experimental and advanced software that drive the equipment. Early experiments began in 1977. Using operationally experienced Navy people to simulate the command center staffs and to evaluate experiments, ACCAT tries out new developments under realistic scenarios. The object is to see if the advanced technologies have C2 utility: whether they have real-world applications, whether operational people can actually use them, and, if so, whether they are an improvement over existing C2 systems. If promising, the new technologies are tested further to see how they might be strengthened for operational use and to determine actual development specifications.

Recent advances elsewhere in defense information-gathering and-processing systems already provide convincing proof that in the years ahead Navy C2 systems can evolve in a direction that will make it easier for the user to receive and assimilate information. This will be done in a number of ways: (1) by improving communication between many shore commands and ships through interactive information exchange networks; (2) by improving sensor and data processing systems; (3) by adding validation and quality control mechanisms; and (4) by exploiting information processing technology to make the machine work on the operator's terms (instead of vice versa).

First, ACCAT is testing technologies that electronically will pull together widely dispersed facilities for information collection, for information processing, and for decision-making—precisely the configuration of facilities in the Navy's C2 architecture. ACCAT employs the ARPANET as a model of the communications network of the future. Developed during the past ten years, the ARPANET is the forerunner of the AUTODIN II digital communications system soon to be used by the Navy and other services. Both systems place special emphasis on the computer's interface to the user.

The ARPANET interface allows operators to do routine things in an easy and enjoyable way. For example, electronic mail systems let users communicate and share files with one another and interact with remote computers for filing, word processing, and for similar edit or update tasks.

ACCAT incorporates another important ARPANET feature—flexible network capabilities—into its experimental operations. Normally, computers cannot communicate with each other because of differences in internal structure which require the data to be presented in different forms. But by translating everything with common protocols into a compatible form, ARPANET allows a network to connect diverse computers and equipments. Similarly, AUTODIN II is expected to provide flexible and responsive interactive capabilities between system and user and between individual systems. Today, ACCAT simulates this kind of intimately tied futuristic architecture and thereby offers insights for efficiently coupling existing and future computer-based systems into Navy C2.

The ARPANET is only the beg inning, for ACCAT will employ and evaluate even more advanced technologies such as the general-purpose distributed database management concept. Under this concept, one can have convenient access to separate items of data stored at any number of facilities in a network. The system handles an operator's query automatically; if the data are not available locally, the system knows where to find them elsewhere and does so through the network. No humans other than the one making the query need get involved. Also, data can be stored and updated simultaneously at several locations or automatically repositioned from one database to another in response to crisis needs or system failures. These features will add greatly to the quality, timeliness, and survivability of information.

For the first time in this country, a software program is being developed which promises such a general-purpose distributed database management concept. The System for Distributed Databases (SOD-I), produced by the Computer Corporation of America in Cambridge, Massachusetts, is to be evaluated for C2 applications in ACCAT. Both the concept and the developing system have enormous significance for the future usability, flexibility, and survivability of Navy C2. They may overcome some long-time problems such as forecasting information requirements for a particular command center ten years in the future, or deciding which data need to be reported to higher headquarters and which do not.

The second kind of advances being tested in ACCAT—largely in the area of artificial intelligence—is local or user-oriented rather than architectural in nature. Artificial intelligence, as defined by Patrick H. Winston in Artificial Intelligence (Reading, MA.: Addison-Wesley Publishing, 1977), "enables computers to do the things that make people seem intelligent." One such advance is a query system known as LADDER (language access to distributed data with error recovery), developed by SRI International.

Since it is rare that a naval officer skilled in military operations will also be skilled in the use of all the specialized data languages for the Navy's many different types of computers, ACCAT, using LADDER, shows the utility and benefits of a single query language-English. In practice, of course, today's LADDER cannot understand all words and expressions, but it can decipher that smaller subset of English used in Navy C2.

With LADDER, the Pentagon computer terminal operator in this article's opening example asked his question in his language, not the computer's: "Which U. S. Navy ships are within 200 miles of Naples?" In the few seconds it took for the computer to answer "Fox and Philadelphia," the computer and the network had engaged in some sophisticated activities. The question had flashed across the continent through the ARPANET to a computer at SRI International in Menlo Park, California. There, a computer program parsed the English question into its several parts, translated these parts into a formal representation understood by the computer, automatically built a computer program to retrieve the requested data, connected via the ARPANET to the computer where the needed data were stored (in this case, at Cambridge, Massachusetts), ran the newly created program, and retrieved the information. The LADDER system then translated its data into an answer in English and zipped it back across the country from Menlo Park to the Pentagon terminal's screen.

When and if LADDER's natural language query system is combined operationally with SDD-I's distributed database management capability, C2 will be transformed in many ways. Commanders and others will be able to ask the computer system questions in simple English and receive a rapid response even if the information has to be searched in databases thousands of miles away.

Alerting is another area for C2 improvement. Rather than asking one-of-a-kind questions of distant databases, watch standers may have more need for repeating a standard question: "Has anything important happened?" They would immediately know of any critical event or key change at the time it is reported. The University of Pennsylvania's Wharton School in Philadelphia has developed a database monitoring and alerting service to meet this requirement. The Pentagon terminal operator in the cited example could have linked to the alerting service at the University of Pennsylvania. He could direct it to notify him when the Fox was more than 200 miles from Naples or, more importantly, whenever the Fox reports an unidentified submarine contact. Notification of these events could come to the operator's console as an audible alarm, as an alert message at a teletype message printer, or as a red flashing circle on his display terminal. Similar techniques could be used to monitor a local database and alert a ship's watch, for instance, the instant a communications link is interrupted or whenever any ship in the task force has labeled a submarine or aircraft contact "unknown." Once terminal operators are freed from the task of checking for recent changes, they can devote time to less routine tasks.

Another user-oriented technology, for transmitting C2 displays, also will be tested with the ARPANET, LADDER, and SDD-1 in ACCAT. Users often prefer to see C2 information in a geographical context or as other graphic presentations instead of as text. Yet, just as different kinds of computers often cannot talk to each other directly, different kinds of displays generally use their own specific graphics code or grid system languages. The graphics language presently under development by the Information Sciences Institute in Los Angeles, California, is designed to resolve these differences so that device-independent graphics can be transmitted and displayed throughout a network. Thus a map or other display seen at one location on one operator's terminal can be sent to another site (or to several sites) where it will appear in the same way, whatever the type of graphics terminal.

Within the year, should the Pentagon terminal operator want to see the Fox's and Philadelphia's positions on a map, he will be able to ask the LADDER system to "Show them to me" and LADDER will get the ships' locations and present them as glowing dots on a color-shaded map, obtained electronically from the situation display program at Los Angeles.

The display might form a window or column on one side to show text data, should the operator ask, "What are the course and speed of the Fox?" Vectors , ship "tags" to identify destination, class, or other category, task element numbers, satellite swaths, and similar information can be added to the map at will in standardized and readily understood symbology. The operator can change color tone to highlight features of interest.

Such developments foretell a future where Navy users will interface directly with C2 systems. Information processing will perform more and more of the tasks that today must be done by the highly trained computer expert. The expert will continue to be needed but he, too, can move toward less routine duties—as shown by two recent developments at the Rand Corporation in Los Angeles. The first of these is a general-purpose interfacing system that allows the expert to quickly and efficiently build an interface package to the user's system. This interface package prompts the user with the same questions and procedural checklists the expert does today. The user himself or a relatively untrained operator assistant can then operate the computerized system without having an expert present.

The second Rand development is a software program that watches the activity of the expert as he operates the C2 system in response to the commander's requests. The program learns by example how to automatically build the new interfaces with promptings by users, following the same conventions and patterns as are in use at that particular facility. Although still in elementary form, this "automatic expert" has progressed to the point that it is ready to be tried in the more challenging ACCAT environment.

Other artificial intelligence systems are further from validation but offer exciting future promise.

These are but a few of the existing and planned technologies that are a part of ACCAT. Together, these contributions are evidence of an invisible revolution that is occurring in information processing and in Navy C2. However, the late 1980s and 1990s will reveal still broader trends and wider aggregations of improvements.

The microelectronics revolution is the main driver. It began 30 years ago when the transistor was developed. An impressive series of technical inventions, still ongoing, will be followed more and more by an impressive series of creative applications of microelectronics. This will continue a trend toward wider use and usability of computers that has been noted over the years on the pages of the Proceedings.

Hardware costs for a given amount of computing power will continue shrinking at about 25% per year. However, because of wider applications and proliferation of microprocessors in the 1980s, software costs will increase to many times that of hardware. Programming costs may begin coming down in the 1990s as the computers and "automatic experts" themselves assume a greater role in preparing software.

The added computer power will often be used for artificial intelligence functions such as the query aids, alerting systems, and display flexibility described earlier. This will be evident even in small terminals on board ships or aircraft far from any large "mainframe" computers.

But the most far-reaching individual improvements in Navy C2 systems will be in handling data. Even now, advanced concepts are being examined for computer correlation and analysis of diverse multi-sensor and other data. Widely separated C2 facilities ashore and afloat will be able to share information interactively with each other through distributed processing and distributed database systems. Potential bottlenecks in communications are being analyzed. Reporting systems will be simplified and speeded up by means of "by exception" report procedures and new technologies. These measures will give C2 functions (as well as computer operations) more flexibility and survivability in dealing with dynamic crises and contingencies.

Progress for future Navy C2 must be attained, of course, without compromising the security of the data, the survivability of the forces, or the commander's personal control over his forces. Major conclusions of a February 1977 congressional report on C2 were that more attention should go to "improving software security" and to C2 survivability in general. Full multilevel security for computer operations—that is, operations that can preserve and protect inputs that have different security classifications—remains an elusive goal but will probably be solved in the 1980s. Meanwhile, ACCAT will test an automated aid for security watch personnel to sanitize queries and responses passing between high and lower security level databases.

Survivability is a problem that will always exist, but a realistic goal is to make C2 as survivable as the forces themselves. In the future, as the role of C2 becomes more vital to combat success, survivability will receive more emphasis to assure that C2 is not lost at the very moment it is needed most. Dispersed and redundant processors will allow increased mobility for C2 centers on a broad variety of platforms. Also anticipated are jam-resistant satellite or other communications capable of operating comfortably in an electronic warfare environment. Combined into a total Navy C2 architecture, these separate improvements should make a monumental difference in the fleet's combat capabilities. Internetted and integrated C2, the "force multiplier" may lead to innovative and unprecedented strategies and tactics. It is plausible that radically different operating concepts will be introduced—such as having a numbered fleet commander operate from a shore location, or placing total C2 responsibility on the joint task force commander. Some current and future observers will object to such steps and to the increasing centralization of authority that is made necessary by supersonic, over-the-horizon weapon threats. Advances in C2 technology and practice often are blamed erroneously for the new trends and pressures for change.

In any case, it already is apparent that Navy C2 has the opportunity over the remainder of the century to move toward revolutionary new capabilities. There are many possible avenues for C2 architectures, compatible command structures, and acquisition of new candidate technologies. In the next ten years, the process of selecting new C2 approaches for the 20th century will be virtually completed. Up to 12 years' lead time is needed between choosing a new approach and fielding the resultant system. Thus, it is essential to learn, as quickly and realistically as possible, the ramifications of candidate technologies for future Navy C2. ACCAT offers a powerful simulation of 1985-95 Navy C2. Helped by these insights, transfer of new C2 technology to the fleet can proceed more rapidly and accurately.

Lieutenant Commander Dietzleris Defense Advanced Research Projects Agency program manager for ACCAT. From 1974-78, on the staff of the Chief of Naval Development, he was administrator for the Navy's exploratory development programs in communications, command, and control.

Colonel Moll is President of Strategy Corporation, an Arlington, Virginia, firm specializing in national defense studies. He entered the Air Force from West Point in 1950 and retired in 1975. In 1976-77, he helped develop the initial concepts and plans for the ACCAT program.

Handling a Spruance-Class Destroyer

By Lieutenant (junior grade) Jim Stavridis, U. S. Navy

As the Foster twists her way into Chinhae, Korea's, narrow channel; as the Kinkaid makes a buoy against a current in Hong Kong; as the Hewitt fights a 30-knot crosswind up the 120-foot channel into Townesville, Australia, the "book" on the handling characteristics of the Spruance-class destroyer is being written and rewritten.

Afterward, in officer's clubs and wardrooms across the Wes tern Pacific and Europe, the experiences will be relived and shared by the junior officers who are driving these gray ladies. It is from such conversations, from the experiences of conning officers on the first of the class, from sea and anchor detail OODs and JOODs, and from sea and replenishment conning officers that this discussion is drawn.

The art of conning the Spruance-class destroyer is unique—a propulsion system encompassing gas turbine power and controllable-reversible pitch propellers. The ship has four gas turbine engines, which generate a total of 80,000 horsepower—facts obtainable from any Spruance-class welcome aboard pamphlet. What is not so apparent from welcome aboard pamphlets is the extreme responsiveness of the turbines, controlled directly from the pilot house. When the conning officer gives a command, his ship's control console operator moves a throttle that directly acts upon the turbines and immediately slows or speeds up the ship. This rapid response is enhanced by the ship's controllable-reversible pitch propellers. At speeds less than 12 knots, instead of increasing shaft rpm, the pitch on the blades is changed to take a larger or smaller bite of water. When backing down, the blades are reversed to bite back into the water, giving an immediate slowing effect. The combination of these factors manifests itself in particular in slower maneuvering situations, such as alongside a pier, because the effect of quick response is enhanced by the pitch. As a general rule, the Spruance-class destroyers will react in half the time of conventional steam plant destroyers.

Although the traditional rule in the fleet has long been to slow at a distance of 50 yards for each knot of overspeed when sliding into station, the Spruance-class rule seems to be closer to 20-25 yards for each knot of overspeed. Thus, when taking station behind a replenishment ship in preparation to come alongside, a drop from 18 knots of stationing speed to 12 knots of base speed should be made at 150 yards (6 knots of overspeed x 25 yards/knot overspeed) instead of the old standard of 300 yards. Inmaneuvering alongside a pier, when faced with slight headway, the time an astern bell should be held to kill headway is miniscule. Instead of waiting for the effect of slight stern way to become apparent, a Spruance conning officer should hit a one-third backing bell, wait for the engine whine, then come to all stop. Holding an astern bell until sternway becomes even slightly apparent will inevitably send the ship backing down. This occurs because the constantly rotating screws, while set with 0% pitch, will usually generate slight stern way.

There are two means of compensating for the tendency of the class to back slightly at all stop. The first is the use of "pitch trim," or setting in a factor of 7-10% ahead pitch. The second method, often used in conjunction with the first, is that of going to secure plant mode—i.e., stopping the shafts altogether when in a position tight alongside the pier instead of waiting for the doubling of the lines before securing. The engines' quick start time (perhaps five minutes to start the shafts rolling again) allows for this approach. The OOD will usually add the 7-10% pitch trim as a matter of course when the ship is approaching the pier, lighting off the shafts while still doubled before getting under way, or even when coming alongside.

A few basic characteristics of the ship and general hand ling rules can be formed. Along her 563-foot length, the pivot point seems to be located directly behind the pilot house. The stern cannot be seen from the bridge wings, and this necessitates a constant flow of information from the fantail lookouts concerning distances to shipping, piers, etc. Several of the class use walkie-talkies between the officers on station to ensure accurate, rapid information flow to the pilot house. This works well. The class seems to back slightly with a one-and-one twist, and makes very slight headway with a two-and-two. One of the most effective overall combinations in the 999 maneuvering combination is a one-and-two twist to go ahead. This has been used with good effect, giving a graceful ahead motion that can move the ship neatly around piers and through tight channels. It has also been used to good effect to compensate for effects of strong crosswinds in tight channels. When going ahead on one shaft, the ship will respond a bit sluggishly at first, at least compared with the razor response of two shafts on the twin rudders, but will move along at just under 5. knots in a harbor. Single-engine maneuvers are also effective alongside a pier.

Insofar as advance and transfer are concerned, the tables promulgated by Litton are reasonably accurate, but experience shows that the navigator must do some "eyeballing." Usually, applying the rudder a bit early gives better results in getting through the turn. Fifteen degrees of rudder is usually effective, unless the ship is making less than 5 knots, then proportionally much more rudder is required to get the ship's head through a channel turn.

The Spruance class is well fitted with deck apparatus fore and aft, and accepts the six standard lines easily. When a strong offsetting wind is encountered, combined with a small pier which gives the long ship an overhang, the rigging of a breast line is advisable. It can be rigged on the forecastle around the ASROC launcher back to a bitt on the opposite side of the ship, or on the bitt just aft of the brakes. Power for the lines is available on two capstans forward and one aft, and the ship can be pulled in on the lines easily if tugs are not being used.

The class rides very well, but the bow is influenced by the wind because of the large superstructure forward and the weight differential. When moving off a pier with an offsetting breeze, touching the inboard engine astern with the rudder away from the pier will move the ship off neatly. Conversely, a wind setting the ship onto the pier is difficult to work against, and use of tugs is very helpful. It is important to remember the engine's quick response to orders when working in close proximity ro a pier. Usually, only a very small amount of time with an astern bell is necessary to begin the ship's movement in that direction. Rudder orders will take quick effect, especially if both engines are used. When sudden swings of the ship's head are not desired, a single engine helps reduce rudder effect.

Because of the large and extremely sensitive sonar dome, it is usually advisable to make up tugs aft of the forward gun mount. They can be made up just forward of the brakes, and given a good size tug, can control the bow easily from that position. Care must be taken to avoid damaging the prominent screw guards when making up an after tug. A Jacob's ladder for a pilot is best rigged on the fantail. Of great help to foreign pilots is a diagram of the sonar dome showing its location in relation to the bow and the gun mount. The drawing should also show the overhang of the dome in relation to the ship's sides. This helps explain the making up of the forward tug to the pilot and also alerts him to the presence of the dome itself in making piers. Probably the best method of getting the ship under way without the assist of tugs, assuming a manageable onsetting wind, is a standard twist against the pier, holding line two until the stern has swung out. Extreme care must be taken to keep the bow from scraping or bumping the pier when this maneuver is undertaken. If a tug is available, it is prudent to use it with an onsetting breeze, having it pull the bow off as the stern is twisted free. All lines can be taken in at once using this maneuver.

Precision anchoring, because of the quick response when speed is taken off, requires cutting the engines somewhat later than one would do with a conventional plant. Coming to all stop at 200 yards from the anchorage point will coast the ship to a stop just about dead on the anchorage, with neutral winds. If a cross wind is experienced, putting the rudder over full about that point in the opposite direction from the wind will assist in preventing being blown off the course. The backing bell can be hit as the ship comes to a stop, but should be left on only briefly, i.e., ten seconds. If no pitch trim is set into the shafts, a 0% pitch trim will usually give the ship a very slight stern way, suitable for letting go the anchor. The ship rides well at anchor, but care should be exercised in a crowded anchorage, since the stern cannot be seen from the normal sight of the quarterdeck amidships, for the swing circle.

In making an approach for an underway replenishment, traditional rules of thumb apply to the Spruance class as far as line up and approach are concerned. As mentioned earlier, the point at which speed is cut is much later than with most other Navy ships. With a 6-knot decrease in speed for the approaching DO, i.e., from 18 to a 12-knot unrep speed, engines can be reduced to the slower speed when the bridge is even with the after deck house of most replenishment classes. While alongside, changes in rpm can be made at one rpm levels, and will take good effect. When breaking away, the quick acceleration dictates that all hands should be inside the skin of the ship, and the rudder should never be allowed to come back in the direction of the replenishment ship.

The class is very effective as a towing platform, but the lack of visibility astern makes it helpful to have an officer with sound-powered phones stationed on the fantail to take control directly or to assist with constant stream of advice and observations to the JOOD/conning officer.

Overall, the ship is quick, responsive, and highly maneuverable with good seakeeping, fine turning, and twisting characteristics. Once one gets the feel of the engines' reactions, the ship is a true joy to drive—a thoroughbred, whether sliding suddenly alongside an oiler or swinging smoothly around the side of Pier Seven at the San Diego Naval Station.

Lieutenant (junior grade) Stavridis recently completed an 18-month tour on board the USS Hewitt (DD-966)—the fourth Spruance. Involved in the Carrier Readiness Improvement program,he is now assigned to the USS Forrestal (CV-59).

Global Hope Aground: Chronicle of an Oil Spill

By Lieutenant Commander Kent W. Mathews, U. S. Coast Guard

On 6 February 1978, in the midst of the worst blizzard to strike the Northeast in 100 years, the 682-foot Greek tanker Global Hope dragged anchor and grounded in Salem Sound, Massachusetts. Of the 340,000gallons of oil aboard, about 83,000 gallons escaped to foul the historic and picturesque beaches of Marblehead, Massachusetts.

Wednesday, 7 February 1978: The Global Hope berthed at New Eng land Power Company's facility at Salem, Massachusetts, and unloaded eight million gallons of number six fuel oil. The 38,889-deadweight ton tanker was built in 1960 at the Eriksbergs Shipbuilders in Germany. In February 1978, the ship was serviceable but neglected.

Saturday, 4 February 1978: The unloading operation was delayed when Coast Guard inspectors ordered transfer operations suspended pending repairs to the ship's steam smothering system, a vital fire extinguishing apparatus. Otherwise, the transfer of the vessel's cargo was completed uneventfully. After taking on fuel, at 2030 she moved to an anchorage in Salem Sound to heat and separate 88,000 gallons of cargo that was contaminated with sea water. She anchored in 40 feet of water, 0.8 miles northeast of a small, obscure land mass called Coney Island—not to be confused with the famous island of the same name in New York—using four shots of chain on the starboard anchor. (On Sunday, the National Weather Service forecasted a severe winter storm to strike the region on the following day.)

Monday, 6 February 1978: First light revealed the dark clouds which herald winter storms in New England. Visibility was good for 13 miles, and wind speeds ranged from 8 to 17 knots. In late afternoon, however, the weather changed significantly.

By 1800, visibility dropped to approximately 100 feet in blowing snow, and wind speeds increased to 42 knots with gusts up to 61 knots. While the storm grew, the Global Hope remained at anchor in the sound. During late afternoon, however, buffeted by high winds, she began to drag anchor and drift to the southwest. By 1810, the vessel radioed C. G. Station Gloucester of engine room flooding. By 2042, she was aground on the shoals off Coney Island.

Along with rescue efforts, the Coast Guard immediately implemented oil pollution response procedures. Much of the effort was automatic.

Captain Walter Folger, U. S. Coast Guard, Chief of the Marine Safety Division, First Coast Guard District, was contacted immediately. He was chairman of the Coastal Regional Response Team (RRT) serving the New England area and a veteran of the previous year's Argo Merchant incident. The team, composed of representatives from selected federal and state agencies, functioned to provide government coordination, advice, and support during pollution emergency.

Another veteran of the Argo Merchant operation was Captain Lynn Hein, U. S. Coast Guard, Commanding Officer, U. S. Coast Guard Marine Safety Office (MSO) Boston, within whose geographic jurisdiction the Global Hope grounded. Captain Hein was the federally appointed on scene coordinator (OSC) and his job was to orchestrate any on-scene response to a Global Hope pollution occurrence. He was contacted within minutes of the grounding.

Within an hour of the grounding, Marine Safety Division watch standers activated the RRT. Because of the severity of the storm, it would be eight days before the team could convene for a meeting. At the time of the tanker's grounding, however, no oil seemed to have escaped.

Shortly after being alerted, the OSC requested assistance from the Coast Guard's Atlantic Strike Team (AST) based at C.G. Air Station Elizabeth City, North Carolina. One of three such units, the AST possessed special expertise in ship salvage, diving, and oil removal methodology. AST equipment included large capacity pumps to transfer oil and water, and open water barriers to boom the vessel. Personnel hastened to load equipment and materials aboard waiting Coast Guard aircraft in preparation for deployment north. Meanwhile, in Portland, Maine, the buoy render Spar (WLB-403) was ordered to pick up additional pumps and a high-seas barrier located with an AST contingent working the earlier barge incident on Piscataua River. The buoy render White Sage (WLM-544), operating from Woods Hole on the south side of Cape Cod, was ordered to stand by to take on AST equipment being flown into C.G. Air Station Cape Cod. Both cutters would make end runs with vital pollution response apparatus around snow-clogged highways.

Tuesday, 7 February 1978: The storm peaked; 30 inches of snow were recorded at Boston’s Logan Airport with accumulations of over four feet inland and drifts up to nine feet throughout the region. Hurricane-force winds blew, and tides ran 10 to 16 feet above normal along the coast. The governor declared a state of emergency. Snow drifts piled over stranded vehicles, clogging highways throughout the commonwealth. Logan Airport was closed to all traffic. The National Guard was activated. Aircraft from C.G. Air Station Cape Cod, 80 miles to the southeast, were unable to launch to conduct pollution surveillance flights. The 210-foot cutter Decisive (WMEC-629), ordered to the Global Hope’s assistance, steamed off Salem after crossing Massachusetts Bay through 30-foot seas. By dusk, it had been snowing for nearly 30 hours.

Wednesday, 8 February 1978: Just before the first light, the blizzard ended, winds slackened, and by 0700 visibility opened to 12 miles. A Coast Guard overflight sighted the first indications of pollution: oil emanating from the vessel’s stern. AST equipment and personnel from Elizabeth City landed at the Air Station on Cape Cod at 0955 aboard C-130 Hercules cargo aircraft. Special pumps were transferred by helicopter to the Global Hope, while bulky open-water booms were hauled overland to the waiting cutter at Woods Hole. The Decisive moved in and removed all crew members with the exception of the master, chief engineer, chief mate, and radio operator. Additional equipment and representatives of the ship’s owners were airlifted into nearby C.G. Station Gloucester where the OSC had established his initial command post. By late afternoon, the Spar moored alongside the grounded vessel with emergency equipment and the White Sage was under way with the containment boom loaded aboard.

Because of the substantial threat of pollution, the OSC requested authority, under federal law from the Commandant, U.S. Coast Guard, to direct all public and private efforts toward removal of pollution and elimination of the threat. Authorization, contingent upon the owner’s failure to take adequate action, was quickly granted. A subsequent vessel survey revealed engine room flooding with 12 to 18 inches of oil floating on the surface. Oil also was confirmed to be escaping from the vessel’s stern.

Although representatives for the owners engaged a local pollution control contractor to contain and remove any oil spilled, the OSC determined that adequate action was not being taken and assumed responsibility for removal of pollutants. AST personnel set up skimming equipment in the engine room and commenced pumping 20,000-25,000 gallons of oil into the port wing tank and 5,000-8,000 gallons into the starboard wing tank. A 500-foot length of 36-inch boom was placed around the stern of the grounded vessel and back anchored to the beach at Coney Island to contain escaping oil.

A boarding party’s initial evaluation revealed a crack in the stern area of the hull, damage to several aft tanks, and a broken rudder post. There was free communication with the sea and between several tanks.

AST resources continued to arrive at Air Station Cape Cod and were shuttled by aircraft and National Guard trucks to staging points near Salem. Roads were barely passable and open for emergency equipment and personnel. By nightfall the command post at Gloucester was in full operation.

Thursday, 9 February 1978: AST personnel, in sounding the port wing tank, discovered the loss of some 15,000 gallons of water-oil mixture which had been transferred from the engine room. The tank had breached and was in communication with the sea. Simultaneously, heavy ground swells in the aftermath of the storm grounded the containment boom around the stern of the vessel, rendering it ineffective in trapping the lost oil. Throughout the day, local residents reported oil coming ashore near Marblehead. Unknown to the OSC, approximately 60,000 gallons had escaped the vessel upon grounding. Inspection disclosed heavy concentrations of oil heretofore hidden by snow. Surveys also revealed wind-driven oil deposited on roofs some 40 feet above the usual high water mark.

Contractors were hired to boom the entire vessel and clean oil from affected shorelines. The National Fish and Wildlife Service was requested to survey the area. Because of the extent of the vessel’s damage and her hard-aground position, the OSC requested assistance from the U.S. Navy’s Supervisor of Salvage (SupSalv).

By late afternoon, a locally contracted 420,000-gallon capacity barge was lightering oil from the tanker under the supervision of the AST commanding officer. Overhead, pollution surveillance flights, with the OSC observers aboard, kept a constant check on the vessel and the nearby shorelines. Weather conditions improved considerably.

Friday, 10 February 1978: A Coast Guard C-130 landed at Logan Airport with SupSalv representative Jerry D. Totten and additional equipment. Mr. Totten reported to the new AST-provided command post which had been flown in and convoyed by state police to a location more accessible to the Global Hope. He analyzed the physical condition of the grounded tanker, proposed salvage plans, and throughout the response persistently assessed the structural stability and integrity of the vessel. He also was tasked with organizing federal salvage and diving activities and with monitoring the efforts of civilian salvors. (That afternoon, the OSC, the SupSalv representative, local divers hired to check the vessel’s hull, and the strike team’s CO determined that, with tug assistance, the vessel could be refloated on a high tide.)

Saturday, 11 February 1978: By late afternoon with a "no cure-no pay" contract between a salvage firm and Global Hope's owners to refloat and tow the vessel to Boston, Coast Guard personnel and equipment were placed on standby to assist the salvors, and control of the vessel was returned to the owners. At the same time the owners declined responsibility for cleanup, which left the OSC with a total and continuing responsibility for oil removal from beaches and, as a preventive measure, from the vessel. Oil unloaded from the Global Hope was transferred to a local shore facility for storage, while oily refuse from beaches was stockpiled inland. (On 11 and 12 February, salvage preparations were undertaken in hopes of refloating at high tide on the afternoon of 13 February. Ballast was transferred, the vessel trimmed by the bow, and tugs turned her 70° to starboard.)

Monday, 13 February 1978: The salvors were unable to dislodge the tanker. Further inspection revealed more serious bottom damage than had been estimated. Port tanks 9, 10, and 11 had been breached with center tanks 10 and 11 and starboard tank 11 possibly being flooded through damaged bulkheads. Upon her failure to refloat, the owners indicated no further immediate interest in salvage, and the salvors withdrew from the venture. The OSC reassumed control of the ship.

Beach cleanup continued during daylight hours. An Environmental Protection Agency (EPA) scientific support coordinator reported to the command post and proceeded to recommend cleanup procedures for the affected shores.

Tuesday, 14 February 1978: Those RRT members and advisors, who were able to make their way into Boston, convened in the Regional Response Center located at the First Coast Guard District Office. The attendees included representatives from Maine and Massachusetts, EPA, Atlantic Strike Team, National Weather Service, Fish and Wildlife Service, Army Corps of Engineers, and the National Marine Fishery Service. Coast Guard legal and public relations representatives were also present. The OSC briefed the team on cleanup activities and the ill-fated attempt to refloat the vessel. His plans called for ball as ting to prevent further movement.

The Commonwealth of Massachusetts representative voiced strong opinions that some federal agency should remove the vessel to prevent her from becoming a permanent monument. This view continued to occupy state and local thinking throughout the state governments' response, although the RRT's and OSC's only statutory interest was the elimination of all pollution threats from the vessel. No federal RRT member agency had authority to undertake salvage for the so le purpose of removing the vessel. The possibility that removal of the pollution threat might best be accomplished by removal of the vessel was considered. To that end, a Navy Harbor Clearance Unit (HCU), experienced in the mechanics of salvage operations, was requested to survey the vessel to evaluate the possibilities for refloating.

During the week of 14 February, oil removal from the Globed Hope progressed as a continuing measure against further pollution. Ashore, the accumulation of oily debris from the beaches became a problem when local towns in which primary disposal sites were located refused to accept additional waste. A third site, approximately 45 miles from the scene, had to be acquired. In addition, on 18 February, small g lobules of oil were discovered along the Wellfleet Beach area of Cape Cod, about 50 nautical miles to the southeast. The Wellfleet tarballs were identified as originating from the Globed Hope. Approximately 1,000 gallons of oil landed on two miles of Cape Cod's inner shoreline. Removal action commenced upon discovery.

Finally, between 17-20 February, the Navy's HCU team completed its inspection and reported its findings to the OSC. Its evaluation was subsequently provided to the SupSalv representative as well as to civilian salvors. It was SupSalv's opinion that the Global Hope could be patched and refloated, but because of the damage done and poor condition of the vessel there was no assurance of a sustained afloat period.

Friday, 24 February 1978: The RRT reconvened in Boston. Authority had been received from Coast Guard headquarters to move, sink, or destroy the vessel as a measure against further pollution. Strong opposition arose against any effort to move the vessel to sea for disposal, however. Of major concern were 20,000 gallons of oil believed to be still in the Global Hope. The second meeting closed with no specific resolution of the problem.

Wednesday, 1 March 1978: At 0830, the Protection and Indemnity Club, which insured the owners against pollution liability, accepted an offer by salvors to refloat the Global Hope and row her to the Bethlehem Steel Shipyard in East Boston. At the RRT meeting that morning, the team was advised of these developments. The RRT considered an alternate plan for sinking should the salvor's efforts fail. This secondary plan was contingent on removal of as much oil as was feasible prior to towing, maintenance of the vessel's structural integrity, and towage during favorable weather.

Wednesday, 8 March 1978: Control of the vessel was transferred to private salvors after she had been patched and her seaworthiness for the short trip to East Boston assured. As the last tug attached its towing hawser, the Global Hope floated free. Several hours later, she moored at the Bethlehem Steel Shipyard where the remaining oil was removed and more effective repairs initiated. She was sold for scrap.

The Global Hope set a new standard for teamwork and cooperation. Her chronicle, however, did not end with re-floatation of the vessel or with her ignominious departure. Coast Guardsmen supervised cleanup, debris removal, and restoration activities along the Marblehead shore until 2 August 1978, when the OSC issued the final pollution report and closed the file on the vessel as an active case. By August, $2.4 million in federal funds had been expended in equipment, materials, and manpower for the cleanup, removal, and pollution prevention efforts.

Today, Marblehead's beaches are clear of oil save for a few telltale stains.

Lieutenant Commander Mathews is assigned co the Marine Environmental Protection Branch of the Marine Safety Division, First Coast Guard District in Boston. He is a member of the Bar of both the State of Maine and the Commonwealth of Massachusetts. He recently received a master's degree in Marine Affairs.

"Punishment, Discipline, and the Legal Profession"

By Lieutenant Thomas M. Bower, Judge Advocate General's Corps, U. S. Naval Reserve

There can be little argument with the main thrusts of Commander Bonds' thesis in "Punishment, Discipline, and the Naval Profession" (December 1978 Proceedings, pp. 43 -49):

- Military discipline is a sine qua non of any effective military unit or undertaking.

- It is the duty and privilege of the military commander to create, nurture, and enforce this discipline.

- Non-judicial punishment or "captain's mast" is at present the single most effective punitive tool at a commanding officer's disposal in his enforcement of military discipline.

- If the power to impose non-judicial punishment is abused to any significant degree, it may be withdrawn.

Unfortunately, in presenting these points, Commander Bonds has overstated his case. "Punishment, Discipline, and the Naval Profession" is so burdened by material omission and inaccuracy born of unfamiliarity with the military justice system that it truly does a disservice to its thesis and will serve only to perpetuate the misinformation about and mistrust of that system.

Commander Bonds' reflections on military justice begin with the following description of its practitioners: "a group of young, idealistic Navy lawyers (members of the Judge Advocate General's Corps) at the base of their specialty's rank pyramid." It would be difficult indeed to create a phrase which more subtly or politely discredits the judgment, the perception, and the attitude of military trial lawyers.

One must ask why Commander Bonds did not mention that military lawyers are the product of a rigorous selection process. All military lawyers are college and law school graduates, have passed difficult bar examinations, been admitted to practice before the highest court of at least one state, been selected from among numerous applicants to be commissioned as naval officers in the Judge Advocate General's Corps (JAGC), and been specifically trained in military law before being certified as military counsel by the Judge Advocate General of the Navy. Nor does Commander Bonds note that this process is so lengthy that JAGC officers typically enter active duty only when they are between three and four years older than their line counterparts.

Nor is military justice the concern only of JAGC officers "at the base of their specialty's rank pyramid." Military trial judges, appellate judges of the Navy Court of Military Review, and the staff judge advocates of general court-martial convening authorities are typically senior officers, either commanders or captains. Many trial and defense counsel are either senior lieutenants or lieutenant commanders, as are the heads of the military justice departments at Naval Legal Service Offices.

Nor can military trial lawyers fairly be characterized as "idealistic," if that term is meant to connote unrealism, unworldliness, or naiveté. Such qualities do not long survive in an officer whose every day is occupied exclusively by crimes, criminals, police officers, and the legal infighting of trial work.

"Punishment, Discipline, and the Naval Profession" then proceeds to bemoan the fact that court-martial requirements have been placed under the aegis of the judge advocates. There is no mention of the vast amount of control over the court-martial process retained by the line commander in his role of convening authority. The convening authority decides whether there will be any court-martial at all and what charges will be referred to that court-martial for trial. He selects the trial counsel, defense counsel, and military judge. He selects the personnel who will sit as members of the court. In short, he exercises an enormous amount of quasi-judicial authority over the entire court-martial. His discretion is not unbridled, to be sure, and his actions with regard to the court-martial are subject to judicial review in order to prevent or correct abuses of his authority. But the legal authority in the hands of the convening authority is enormous. In addition, contrary to Commander Bonds' assertion, an accused does not have a right to counsel at a summary court-martial.

When a line commander complains of the legal technicalities which make the conduct of a court-martial such a harrowing experience for many commands, he should also consider exactly why such technicalities exist. They do so to protect legal rights and the integrity of the law. Legal "technicalities" are particularly important in the military context, where a non-lawyer line commander bent on enforcing discipline in his command is able to decide what to charge an accused with and handpicks the accused's defense counsel, the prosecutor, the judge, and the jury. It should not be forgotten that the Uniform Code of Military Justice was enacted by Congress in response to widespread, deliberate, and unconscionable abuses of military authority during World War II.Nor should it be forgotten that recent decisions of military appellate courts reveal continued abuses by modern-day commanding officers and law enforcement personnel. One can only speculate as to whether a military commander would complain about legal "technicalities" were he facing trial by court-martial with the possibility of imprisonment, fine, dismissal, and a federal conviction. Such complaints serve only to reinforce the perception, common among military trial lawyers, that line commanders view courts-martial as a species of administrative procedure which must, regrettably, be completed before punishment can be imposed on an accused whose guilt has been predetermined.

The article goes on to point out:

"In military service, the rights of the individual are important but not at the expense of the predictable behavior necessary for interdependence and survival…

"Some judge advocates prosecuting cases or serving as military judges apparently see their roles as more consonant with their training in the civilian law and act accordingly in their pursuit of individual rights as an ultimate objective." (Emphasis in original.)

Whether or not military lawyers agree with the proposition that the rights of military society ought to be paramount to those of a military individual, military law does not agree. Military law says that servicemen are not divested of the rights they are paid to defend. A citizen does not surrender the law's protection of his rights by donning a uniform.

Military judges, like all officers, are sworn to uphold and defend the Constitution of the United States. Unlike other officers, they are also sworn to decide cases in conformity with the law. All lawyers take similar oaths and are, furthermore, bound in their professional conduct by the canons of ethics of the legal profession (made specifically applicable to Navy judge advocates by order of the Judge Advocate General and the Secretary of the Navy). The various oaths and disciplinary rules of the legal profession are not matters which any lawyer can safely ignore. To complain that military judges and prosecutors act in a manner which protects individual rights at the expense of discipline is thus the precise logical equivalent of complaining that they obey, support, and defend the law.

"Punishment, Discipline, and the Naval Profession" proposes that the problem with judge advocates is that they are simply not attuned to the needs of the "real" Navy. What, after all, can a corps of professional "desk jockeys" know of life at sea, with its perils, demands, discomforts, and need for discipline?

First, it requires no great exercise in imagination to understand that emergencies at sea, even in peacetime, demand precisely the sort of discipline which Commander Bonds discusses. Second, a great many judge advocates have prior experience in operational billets. When Commander Bonds' article was published, for example, 8 of the 14 judge advocates attached to Naval Legal Service Office, Pearl Harbor, Hawaii, had prior non-legal military experience. Third, the shore establishment, even the JAGC, is part of the Navy. Judge advocates are commissioned officers and face many of the same problems their seagoing brothers experience, though seldom in life-threatening situations. Judge advocates can have their lawful orders disobeyed, their personnel can absent themselves without authority, they can be the victims of disrespect by subordinates, their offices can be burglarized, etc., and they regard such offenses with precisely the same degree of delight as does Commander Bonds.

Lawyers and judges must take the law as they find it and, like any other citizen, work within the legal system to change those laws which have outlived their usefulness or were ill-conceived to begin with. By identifying the JAGC—a visible target—as the enemy, "Punishment, Discipline, and the Naval Profession" fails to uncover the real enemy: a legal systemof enormous procedural complexity, onerous expense, and unpredictable results, overseen by a willful appellate tribunal largely isolated from the realities of military society. Few judge advocates would argue with the line commander's indictment of some aspects of this system. Even fewer, however, can stand idly by while being excoriated for professional dereliction by a layman inexperienced in the workings of the legal profession.

On another level, "Punishment, Discipline, and the Naval Profession" appears to have been focused far too narrowly, as is demonstrated by the very title of that article. Punishment is not the same as discipline. Indeed, when punishment becomes necessary, discipline has already broken down. We ought to be at least as concerned about lowered enlistment qualifications, negligent recruiting practices, insubstantial boot camps, overburdened division officers, inadequate training, thoughtless and uninspired management instead of leadership, inhumane treatment, alcohol abuse, and lack of job satisfaction as we are about punishing the disciplinary breaches which result from these conditions.

Finally, Commander Bonds' article is a striking example of the suspicion with which the law and lawyers are regarded by a great many line commanders, particularly in matters of military justice. The intent of my response is not to hurl down the gauntlet to Commander Bonds or the line community. JAGC officers are acutely aware that their function is one of supporting the operating forces. It is difficult, however, to support anyone who will not ask for advice or who, when he receives it, reacts with rancor and skepticism. Among the most frequently voiced complaints of JAGC officers is that convening authorities take legally significant actions, such as authorizing searches, confining accused in advance of trial, convening courts-martial, and referring charges to trial, without first seeking the advice of a lawyer; any of which can result in frustrating legal roadblocks in the course of courts-martial.

JAGC officers share the concern for good order and discipline which occupies the Navy at large. If lawyers and line commanders can stop hurling mutual recriminations borne of mutual ignorance, we will find that we share a great many problems. It would be very surprising if we did not also find that we can work together to reestablish military discipline in the naval service.

With a B. A. from Cornell and a Juris Doctor from Columbia, Lieutenant Bower was commissioned an Ensign, JAGC, USNR in 1973. Upon graduating from the Naval Justice School, NETC, Newport, Rhode Island, he served as trial counsel, Naval Legal Office, Pearl Harbor, Hawaii. He is presently Staff Judge Advocate for Naval Station, Pearl Harbor.

P. R. C. Submarine-Launched Ballistic Missile Development

By Lieutenant Commander Bradley Hahn, U. S. Naval Reserve (Retired)

The Sino-Soviet Friendship Treaty of 1950 was the initial impetus behind the development of a modern Chinese "People's Navy" submarine force. Following the Korean Armistice in 1953, a Soviet Naval Mission in China provided the Chinese Navy with extensive amounts of post-World War II naval hardware and equipment.

According to Soviet Colonel Oleg Penkovsky's ThePenkovsky Papers (Garden City, NY: Doubleday, 1965), through August 1962, China had not been given a single nuclear missile, nor any other kind of nuclear weapons. The Chinese had been given conventional missiles just as other countries of the people's democracies. "The Chinese themselves," Penkovsky wrote, "can manufacture conventional missiles, using our blueprints…For a long time there was a Foreign Department in the Moscow Academy [Dzerzhinsky Military Engineering Artillery Academy—higher educational institute for conventional and missile artillery] in which officers of the satellite countries of Eastern Europe, as well as Korea and China, were trained."

From 1959 through 1963, the P.R.C.'s investigation of foreign strategic missile systems design concepts led to the research and development of a single-stage, liquid-fueled medium-range ballistic missile (MRBM), designated the CSS-1. (Strategic missile systems having a significant influence on Chinese design concepts are categorized in Table 1.) The P .R.C.'s first-generation CSS-1 appears to be patterned after the Soviet SS-3 or SS-4 systems. On 27 October 1966, in Kansu Province, the P. R. C. Strategic Rocket Forces launched one CSS-1 MRBM which traveled 1,750 kilometers, detonating a 20-kiloton atomic warhead prior to impact. This missile firing was the first operational test of a P. R. C. designed and produced nuclear warhead for an operational ballistic missile system.

Table 1. Foreign Strategic Missile Systems | |||||||

| U.S.S.R. | U.S.S.R. | U.S.S.R. | U.S. | U.S. | U.S. | France |

Designation | SS-3 | SS-4 | SS-9 | LCM-25C | A-1 | A-2 | M-1 |

Type | MRBM | MRBM | ICBM | ICBM | SLBM | SLBM | SLBM |

I.O.C. (Initial operational capability) | Prior 1960 | Prior 1961 | 1966 | 1963 | 1960 | 1961 | 1966-67 |

Dimensions (meters) | 21 x 1.6 | 21 x 1.6 | 37 x 3.4 | 31.3 x 3 | 8.6 x 1.33 | 9.4 x 1.3 | 10.4 x 1.5 |

No. Stages | 1 | 1 | 3 | 2 | 2 | 2 | 2 |

Propellant | Liquid | Liquid | Liquid | Liquid | Solid | Solid | Solid |

Guidance | Radio command | Radio command/ inertial | Inertial | Inertial | Inertial | Inertial | Inertial |

Warhead | Nuclear/ H.E. | 1 MT/ H.E. | 20 MT | 5+ MT | Nuclear | Nuclear | 500 KT |

Launch weight (kilograms) | 26,000 | 27,000 | 200,000 | 149,700 | 13,650 | 14,000 | 18,000 |

Range (kilometers) | 800-1,200 | 1,500-1,800 | 12,000 | 15,000 | 2,200 | 2,760 | 2,500 |

Table 2. P.R.C. Strategic Missile Programs | |||||

Designator | CSS-1 | CSS-2 | CSS-3 | CSS-X-4 | CSS-NX |

Type | MRBM | IRBM | ICBM | ICBM | SLBM |